Biomedical Engineering Reference

In-Depth Information

(A)

(B)

Compact TiO

2

Voltage source

Most

electrolytes

e

-

Ti

∆

U

M

t

≈

2.5 nm/V x U

Ti

Self-organized TiO

2

nanotubes

MO

x

∆

U

Anode

Cathode

Electrolytes

containing F

-

(optimized

conditions)

Film formation:

M

°

8

→

M

2+

+ 2e

-

M

2+

+ H

2

O /OH

-

→

M(OH)

2

→

MO

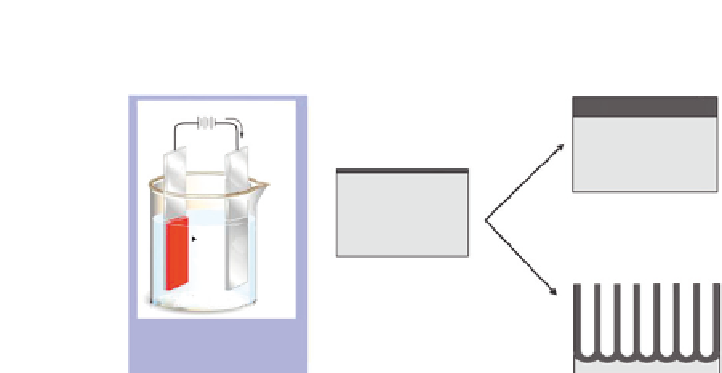

FIGURE 7.1

Schematic setup for anodization experiments. Anodization leads to an

oxidation of metal species that form a solid oxide on the metal surface (A).

(B) Depending on the anodization conditions (mainly potential, electrolyte,

temperature), the solid oxide layer can be either compact, or nanotubular

(nanoporous)

[11]

.

7.2

TITANIUM NANOTUBES

In the following years, successful chemical synthesis of titanium dioxide (TiO

2

) nanotubes by ano-

dization technique was reported

[6-8]

. Anodization is a widely used technique to produce protective

oxide layer on valve metals like titanium. This technique has attracted great attention in recent years

due to its simplicity as well as reproducibility of the results obtained

[9,10]

. Anodization is an elec-

trolytic passivation technique used to increase the thickness of the natural oxide layer on metal sur-

faces. The schematic representation of TiO

2

nanotube fabrication by anodization is shown in

Figure

7.1

[11]

.

The thickness and structure of the oxide layers formed (amorphous or crystalline) depends on the

applied potential between the electrodes, duration of anodization process, and the chemical composi-

tion of electrolyte used

[12,13]

. The structure of the oxide film formed on titanium is amorphous at

low voltages (below 20V) and crystalline at higher voltages

[14]

. Depending on the anodizing condi-

tions, the crystal structure has been reported to be anatase, a mixture of anatase and rutile, or rutile

(mineral forms of TiO

2

)

[15,16]

.

A completely different growth morphology leading to self-organized and ordered nanotubular,

nanoporous structures of TiO

2

has been obtained when electrolytes containing fluoride ions and suit-

able anodization conditions were used

[11]

. Recent

in-vitro

study of osteoblasts on anodized nano-

tubular titanium substrates has been reported to enhance cell adhesion and proliferation

[17]

. These

nanotube-like pores possess higher surface energy and wettability compared to unanodized tita-

nium

[18]

. Furthermore, it has been suggested that TiO

2

with a 3-D micro/nanoporous structure may

enhance hydroxyapatite formability when compared to dense TiO

2

[19]

. When the anodized titanium

substrates were placed in simulated body fluid (SBF), bone-like apatite layer was formed on TiO

2