Biomedical Engineering Reference

In-Depth Information

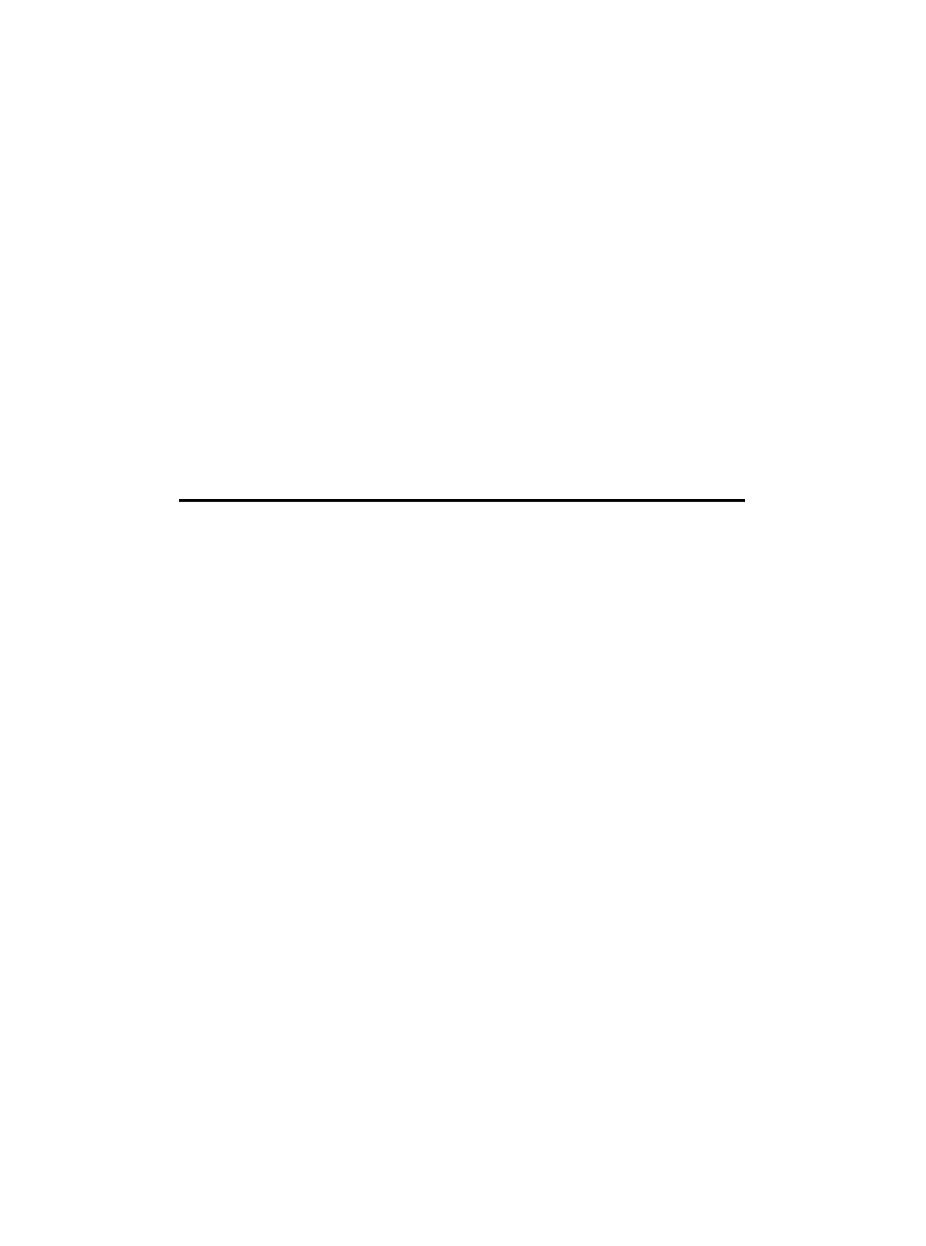

TABLE 4.2

Representative Water Vapor Transmission Rates of Various

Food Packaging Polymers at 38°C and 90% Relative Humidity

Water Vapor Transmission Rate

Polymer

(g.mm.m

-2

.day

-1

)

Polyvinylidene chloride (PVDC)

Polypropylene (PP), biaxially oriented

High density polyethylene (HDPE)

Polyvinyl chloride (PVC), rigid

Low density polyethylene (LDPE)

Polyethylene terephthalate (PET)

Ethylene vinyl alcohol copolymer (EVOH)

27 mol% ethylene

44 mol% ethylene

Nylon 6, unoriented

0.036

0.10

0.12

0.36

0.39

0.7

2.24

0.56

5.9

Adapted from Brown.

14

testing methodologies that may be different from the application conditions, perme-

ability data from packaging handbooks should be used only to compare packaging

alternatives. Estimates of changes in the moisture content of a packaged food during

storage can be calculated for any packages with known WVTR properties and

geometry, and for various lengths of exposure time by knowing the initial and

tolerable moisture range of the product (minimum and maximum) and the ambient

conditions of temperature and humidity.

1,14

Oxygen and Other Gases

Oxygen is a critical mass transfer component in a number of deteriorative reactions

that can have an effect on the shelf life of many packaged foods. Of major concern

are oxidative reactions associated with food components, including lipid oxidation

and the subsequent development of rancid flavors, as well as color and nutritive

changes, non-enzymic browning, and vitamin C degradation. The presence of oxygen

during processing and storage also permits spoilage due to growth of aerobic micro-

organisms and promotes various enzyme catalyzed reactions. On the other hand, the

depletion of oxygen due to respiration can lead to other deteriorative effects, such

as anaerobic microbial spoilage in specific products like sealed plastic packages of

fresh fruits and vegetables. The shelf life of oxygen-sensitive packaged food products

depends on exposure to oxygen during processing; the level of oxygen incorporated

into the sealed package; and the amount of oxygen ingress into the package during

storage, either through permeable packaging materials or through seals and closures.

A number of packaging innovations have been developed to control oxygen

incorporation and ingress into a package based on oxygen-absorbing components

or scavengers. These are successfully used mainly in Japan and Europe.

21,22

The

absorbents consist of easily oxidizable substances which can be inorganic (e.g., iron

Search WWH ::

Custom Search