Biomedical Engineering Reference

In-Depth Information

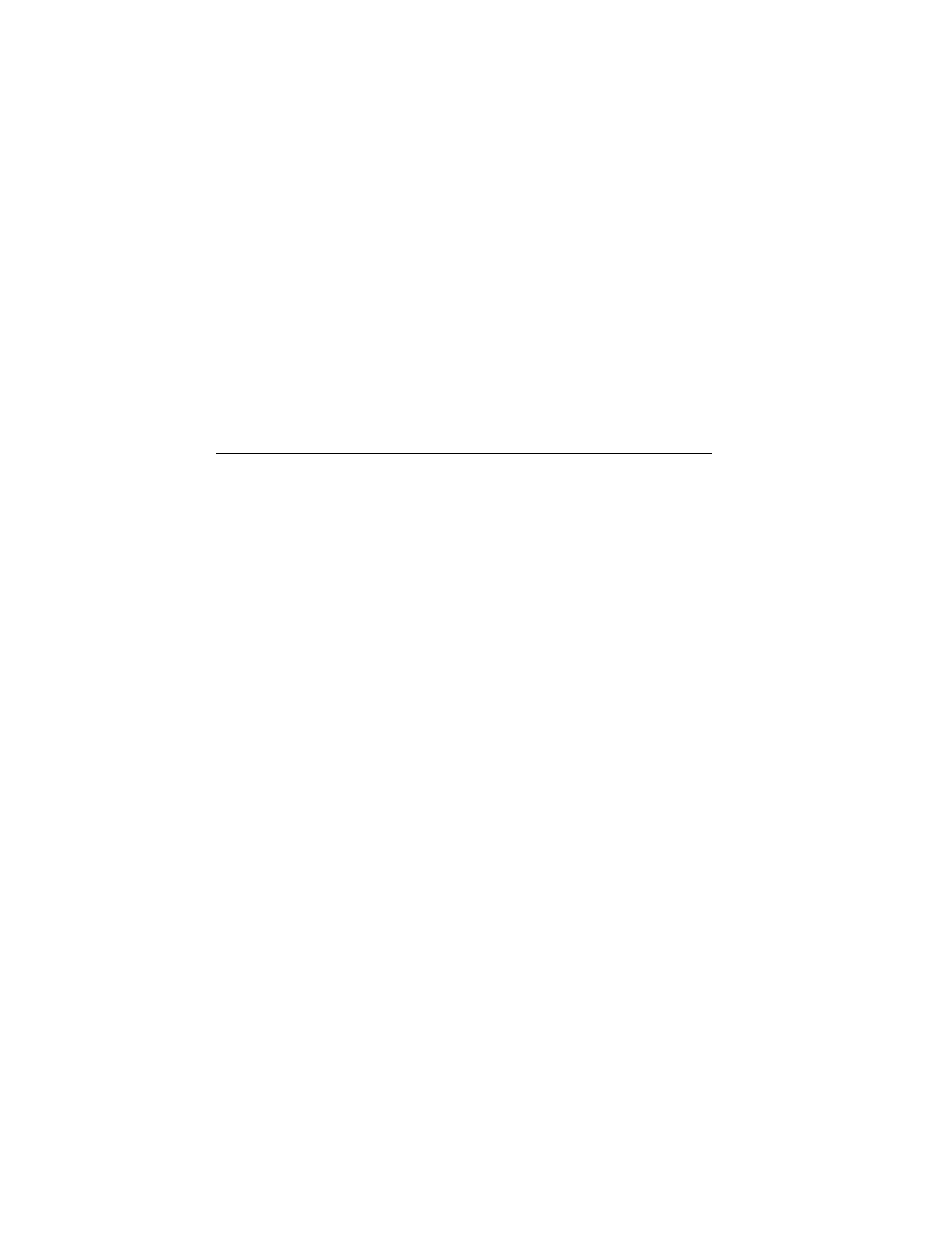

TABLE 4.1

Oxygen and Water Vapor Transmission Rates of Some

Biaxially Oriented Polypropylene (OPP) Films

OTR

a

WVTR

b

OPP type

(cm

3

/m

2

day atm)

(g/m

2

day)

Clear, 30 µm

<1500

<5.5

Acrylic coated 2 sides, 30 µm

650

4.0

Metallized, 30 µm

<120

<0.8

PVDC coated 2 sides, 28 µm

16

5.0

Metallized/acrylic coated, 21 µm

1-2

1.0-1.5

a

23 ± 2°C and 90% RH.

b

38°C and 90% RH.

OTR = oxygen transmision rate; WVTR = water vapor transmission rate.

Adapted from Reilly and Man.

11

process can be used to design packages for specific products, such as fresh lettuce

mix, where the permeation of carbon dioxide out of a package would be considered

desirable.

Plasticfilms and containers vary greatly in the degree of protection they can

provide as a food packaging material. For many flexible packaging applications,

mono-layer materials have been largely replaced by multi-layer laminates, coated

films, and metallized film structures with greatly improved barrier properties against

light and oxygen. Manufacturing techniques such as coextrusion, lamination, and

metallization can be employed to produce multi-layer structures with barrier prop-

erties designed to meet specific product shelf life requirements. For example, met-

allized biaxially oriented polypropylene (OPP) film is commonly used for packaging

potato chips which require a good barrier to oxygen and light (to prevent oxidative

rancidity), and to water vapor (to prevent moisture uptake and to maintain crispness).

Whilefilm thickness plays an important role in water vapor and oxygen transmission

rates of OPP films, metallization and/or coatings with additional barrier materials

such as polyvinylidene chloride (PVDC) and acrylic polymers can greatly enhance

the barrier properties of films, as shown in

Table 4.1

for OPP.

E

NVIRONMENTAL

F

ACTORS

The climatic environment (e.g., moisture, oxygen, light, temperature, aromas) as

well as the physical distribution and storage environment (e.g., shock, vibration,

compressive loading) are major extrinsic factors involved in the numerous deterio-

rative reactions and physical damage that can lead to losses in food quality and

decreased shelf life. Details of specific deteriorative reactions and their mechanisms

have been described by Fennema and Tannenbaum.

12

The chemical deterioration of packaged foods is largely due to transfers of

oxygen, water vapor, aromas, and contaminants between the internal environment

Search WWH ::

Custom Search