Biomedical Engineering Reference

In-Depth Information

sufficiently high molecular weight polyester. Few of the studies associated with aliphatic polyester

conducted the molecular weight studies.

3.2.4

Electrospinning

An alternate technique to fabricate polymer/CNT composite fibers is electrospinning. This tech-

nique allows the alignment of the CNTs along the fiber axis. The diameter of electrospun polymeric

fibers ranges from tens of nanometers to several microns. Many biologically functional molecules

and cells often interact at the nanoscale level making these electrospun matrix attractive for tissue

engineering. A number of CNT/polymer composites (mostly consisting of MWNT) have been

successfully electrospun making it a versatile fiber processing technique. The alignment of the

CNT in the polymer enhances the aspect ratio for reinforcing and increases the area for interfacial

bonding

[88]

.

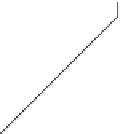

The elements of a basic electrospinning unit include an electrode connected to a high voltage

power supply that is inserted into a syringe-like container containing the polymeric solution.

Connected to the syringe is a capillary. The syringe

capillary setup can be mounted vertically

[89]

, horizontally

[90]

, or tilted at a defined angle

[91]

. A grounded collector plate, which is

connected to the other end of the electrode, is placed at a distance of 10

30 cm from the tip of the

capillary (

Figure 3.1

).

The polymer solution at the end of the capillary upon the application of high voltage becomes

charged. As the voltage is increased, a charge is induced on the surface of the liquid. Mutual charge

repulsion leads to the development of force directly opposite to the surface tension. A jet is ejected

Taylor cone

Whipping

instability

Syringe pump

High-voltage

DC supply

HVDC

Rotating and translating

grounded collector

FIGURE 3.1

Schematic of a typical electrospinning system. If the electrostatic charge is able to overcome the surface

tension, the Taylor cone is formed and the solution is ejected from the apex of the needle. Whipping instability

depicted here further thins the fiber. It is collected on the drum which can be rotated to further align the fiber.

From Ref.

[92]

.