Biomedical Engineering Reference

In-Depth Information

CNTs showed a uniform dispersion in the copolymer matrix, whereas severe agglomeration

occurred at 5 wt % CNTs due to CNT entanglement and resulted in high porosity. The mechanical

properties of PLC composite with 2 wt % CNTs increased remarkably, and an increase in elastic

modulus by 100% and tensile strength by 160% were detected without any adverse effect on the

ductility of PLC up to 240% elongation. An in vitro biocompatibility study on the PLC

CNT com-

posites showed an increase in the viability of human osteoblast cells compared with the PLC

matrix, which was attributed to the combined effect of CNT content and surface roughness of the

composite films. Mattioli-Belmonte et al.

[23]

reported the mechanical, thermal, and biological

characterization of a solid free form microfabricated polycaprolactone (PCL)

CNT composite. By

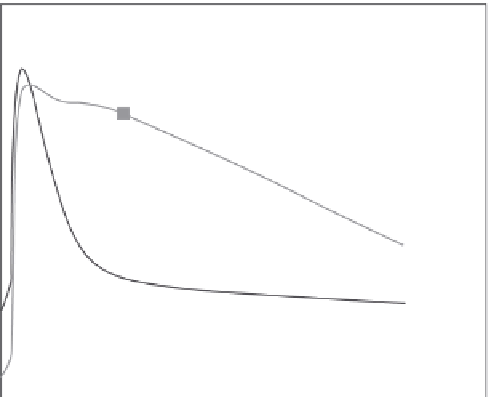

changing the ratio of CNTs to PCL, the elastic modulus of the nanocomposites varied between

10 MPa and 75 MPa (

Figure 18.2

). When the CNT concentration in the composite reached 12.5 mg/ml,

the elastic modulus achieved the maximum point. If CNT concentrations were high, their inhomo-

geneous dispersion in the composite materials would lead to an abrupt decrease of elastic modulus

as well as an increase in fragility. Pan et al.

[24]

fabricated MWCNT/PCL composite scaffolds by

the solution evaporation technique. Their results also showed that mechanical properties of the

composite scaffolds were improved with the addition of MWCNTs (0.25

2 wt %).

Sitharaman et al.

[25]

examined the suitability of various nanocomposite materials made of

poly(propylene fumarate) (PPF) and SWCNT for potential use as bone tissue engineering scaffolds.

They demonstrated that SWCNTs, especially ultra-short SWCNTs (US-tube), could significantly

90

PCL1

PCL2

80

B

70

B

C

D

60

50

C

40

E

D

30

A

E

20

10

A

0

0

50

100

150

200

250

300

CNT concentration (mg/mL)

FIGURE 18.2

Elastic modulus of composite spin coated films as function of CNT concentration. The errors are of the order

of 4%. The PCL (MW65,000) polymer was dissolved in chloroform to give 0.1 g/ml and 0.2 g/ml solutions

(w/v), referred to as solutions PCL1 and PCL2, respectively.

Reproduced with permission from Ref.

[23]

.