Biomedical Engineering Reference

In-Depth Information

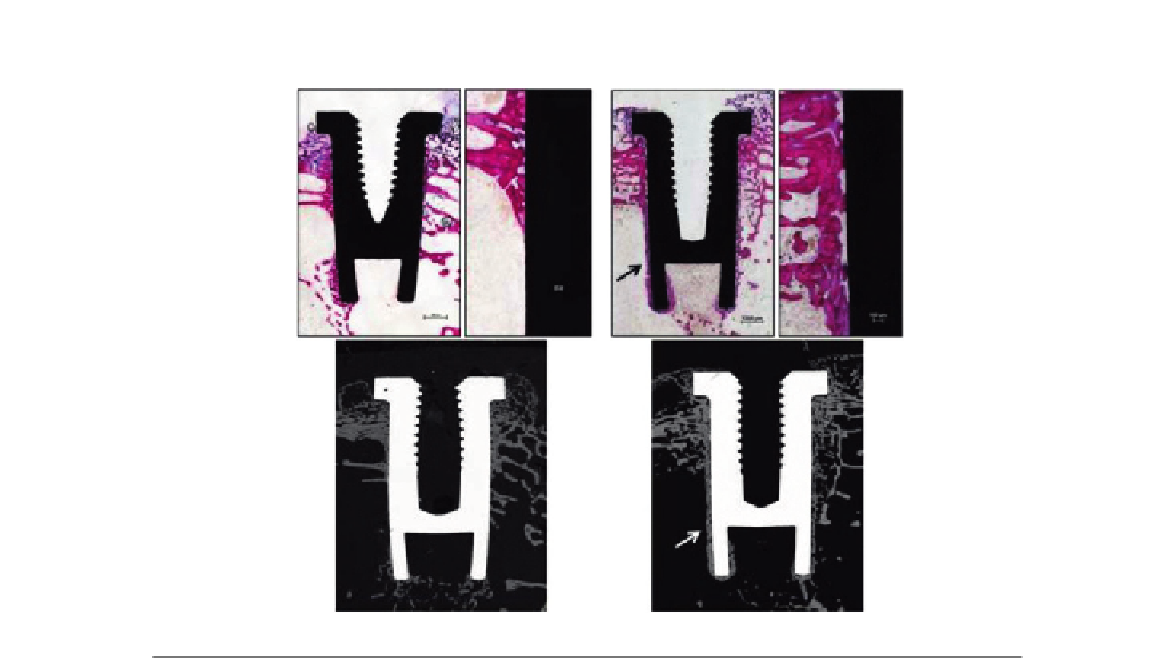

Ti

CaP

FIGURE 16.6

Micrographs showing the osseointegration of bare titanium (Ti) and CaP-coated implants after implantation in

femoral condyles of rabbits for 4 weeks. Note the direct bone apposition on CaP-coated implants (arrows) on

both histology (basic fuchsine, toluidine blue staining) and back-scattered electron microscopy (BSEM)

images.

implant interface are influenced by the chemistry, topography, and wettability of dental implant

surfaces. The challenge in developing new implant surface is increasing the clinical success rate as

well as decreasing the tissue healing time for immediate loading of implants, particularly in esthetic

situations

[66

68]

. One of the objectives is to develop implant surfaces having predictable, con-

trolled, and guided tissue healing. For instance, surfaces that promote contact osteogenesis rather

than distance osteogenesis would be desired in bone site while intimate fibrous tissue healing would

be in the gingival tissue (

Figure 16.1

). In order to enhance this intimate contact between tissues

and implant, surface treatments at the nanometer scale have been performed on metal implants and

tested in various animal models. Implant surface with various roughness has been used to increase

the total area available for osteoapposition. Kubo et al.

[66]

observed a substantial increase by 3.1

times in bone

titanium interfacial strength by Ti nanotube (300 nm) at 2 weeks of implantation in

femur of rats. These results suggest the establishment of nanostructured surfaces for improved

osteoconductivity. Moreover, Ogawa et al.

[69]

have prepared Ti nanostructure by physical vapor

deposition and tested their osseointegration in femur of rats. They found an increased surface area

by up to 40% and a greater strength of osseointegration for the nanostructured compared to an