Biomedical Engineering Reference

In-Depth Information

1000

1

0

c

e

3

−

1000

2

−

2000

d

−

3000

20

60

100

140

180

220

260

Scratch distance (

µ

m)

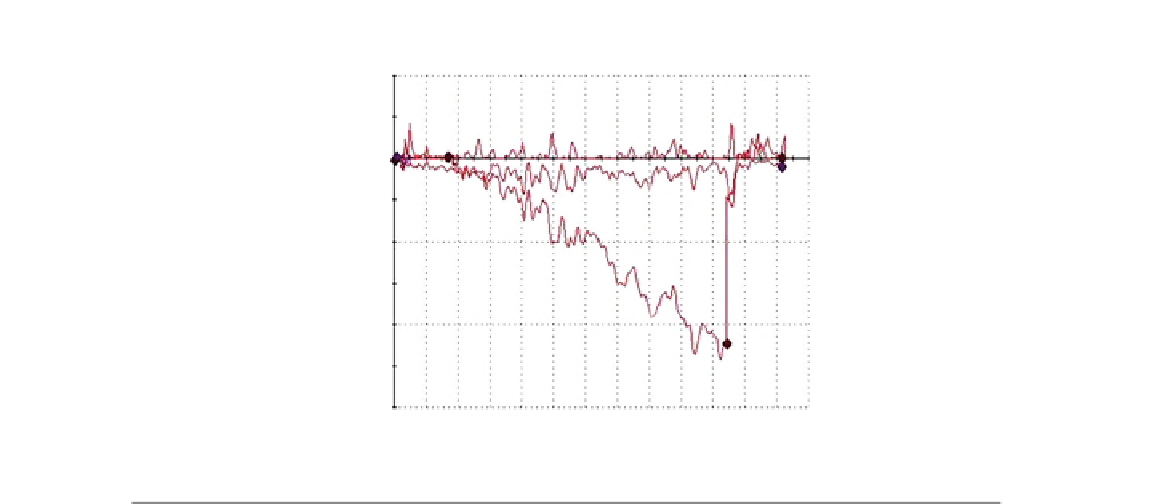

FIGURE 13.9

Scratch test performed using the nanoindenter showing an almost complete recovery of the Co

IF-coated

file after release of the load. (1) Surface profile of the pristine surface, (2) scratch test with increasing force,

up to 30 mN, and (3) surface profiling after the pressure release.

1

fully duplicated in the laboratory. Nevertheless, these experiments were conducted in various best-

fit models.

The following sections describe various experimental friction models used to evaluate the effect

of IF coatings of orthodontic wires on the friction force.

13.4.4.1

SS wires with IF-WS

2

NP impregnated in electroless Ni

P film

In the first set of experiments, a system which simulated the sliding of a tooth along an archwire,

described previously by Redlich et al.

[40]

was utilized. Upper incisor SS brackets were bonded to

aluminum plates by a bracket-mounting apparatus. This apparatus ensured the accurate and similar

positioning of the brackets on the plates. The plates were then connected to the base of a universal

mechanical testing apparatus (Instron 4502) through a device with three different notches angulated

at 0

,5

, and 10

to the long axis of the device (

Figure 13.10

). Angulations represent the contact

angle between the wire and bracket during the movement of the tooth.

In this setup, the tensile tester was set to move the bracket down along the wire at a constant

speed of 10 mm/min to a distance of 5 mm. The test begins with a steady increase in the force and

reaches a maximum when movement begins on the wire. This maximum force represents the static

friction and it is the force that is of interest in this case. A run-in period was needed before testing

the coated wires with Instron. The run-in was carried out by repeated back and forth movements of

the wire in a bracket slot before connecting the wire to the Instron. A new bracket was used for

each testing. The highest angle was tested in the dry and wet mode. Deionized water was used to

simulate the wet conditions in the mouth.

Table 13.1

summarizes the results of the mechanical