Biomedical Engineering Reference

In-Depth Information

Cl

(A)

Co

Atomic%

Element

O

28.41

S

7.00

Co

Cl

1.78

O

Ti

W

Ti

2.91

S

Co

Co

55.38

Cl

Ti

W

W

4.52

W

W

0

2

4

6

8

10

(B)

(C)

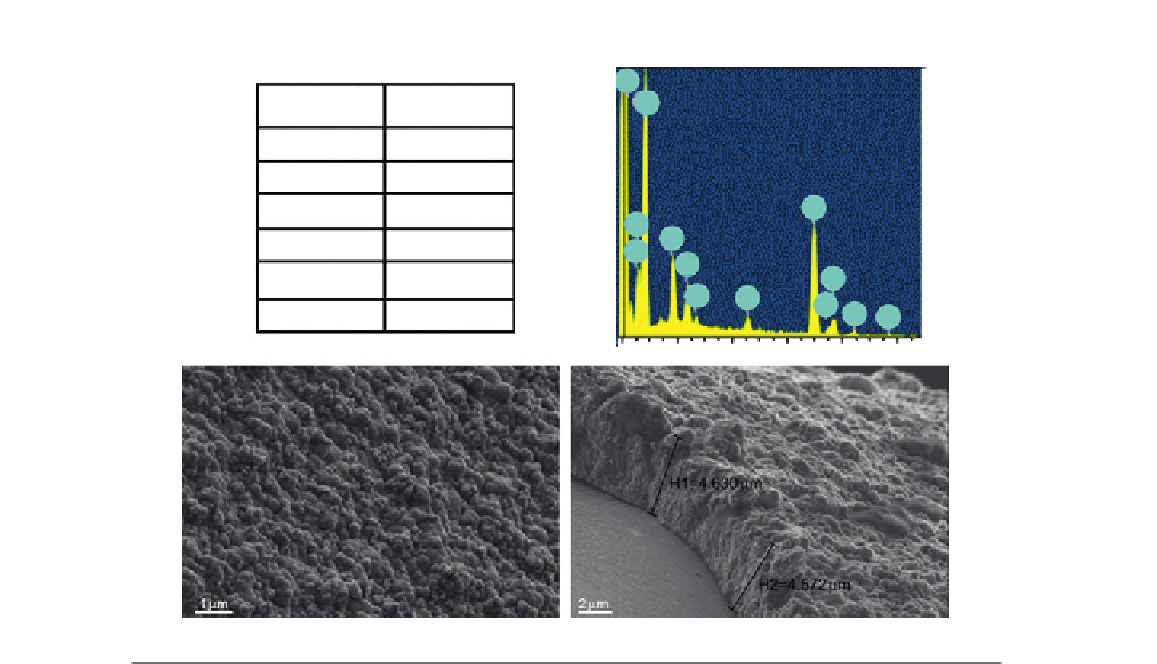

FIGURE 13.6

SEM/EDS analysis of the electrodeposited cobalt film onto Ni

Ti surface.

the reduced friction between the coated file and the surrounding. These methods are possibly also

applicable to a variety of other Ni

Ti-based medical devices where fatigue and consequent failure

are of relevance

[38]

.

Figure 13.6

shows the SEM/EDS (energy dispersive X-ray analysis mounted

on scanning electron microscope) analysis of such coatings. A uniform coating a few microns thick

was thus obtained. The atomic ratio of W/Co

12.5 indicates that substantial amount of IF-WS

2

NP was incorporated into these coatings. The surface is rather rough which suggests that the parti-

tion of the IF NP along the Co-film coating is possibly not uniform and the film surface is enriched

with respect to the NP. XRD of the film (

Figure 13.7

) shows again a distinct (0002) peak of the

IF-WS

2

at 14.2

.

B

13.4.3

Coating adhesion and wear

The adhesion of the cobalt coating to the Ni

Ti orthodontic wires was determined by inspecting

the folded wire, which showed excellent integrity of the film (see

Figure 13.8

).

Figure 13.9

shows a scratch test of the Co

1

IF coating with nanoindenter. The test is done by

profiling the surface of

IF film. This is followed

by scratching it with increasing loads up to a maximal value of 30 mN. As a test of the quality of the

coated surface, a final surface profiling shows little variation with respect to the original file surface.

the Ni

Ti

file surface coated with Co

1