Biomedical Engineering Reference

In-Depth Information

(B)

(A)

FIGURE 13.4

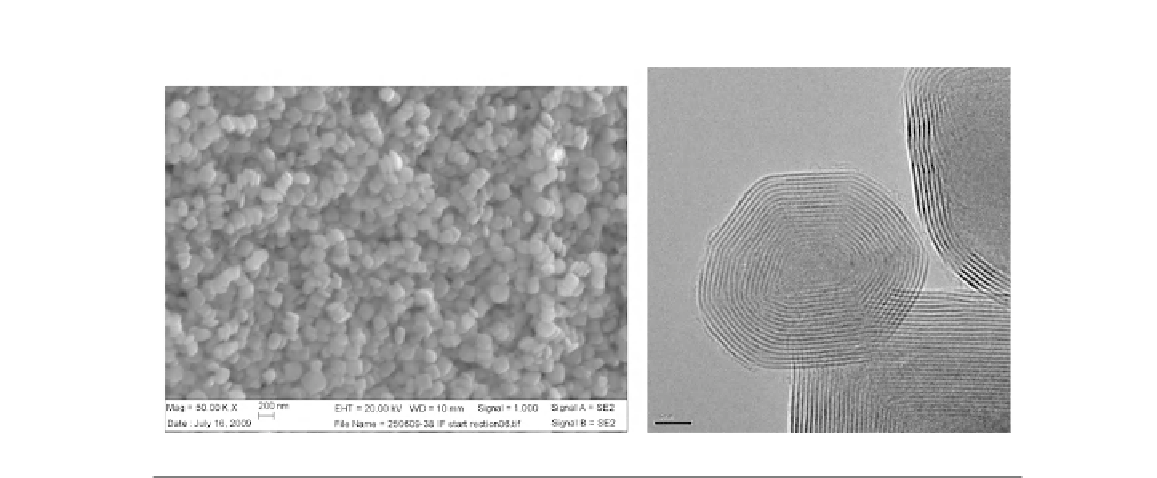

(A) SEM micrograph of assortment of IF-MoS

2

nanoparticles (scale bar is 200 nm); (B) TEM micrograph of

one such nanoparticle (scale bar 5 nm). Note the (nested) closed MoS

2

layers.

The synthesis of IF-MoS

2

NP from MoO

3

powder was found to be more complex. The reason

for these difficulties was the high volatility of the oxide powder above 700

C. Following a con-

certed effort to elucidate the growth mechanism of IF-MoS

2

NP

[26]

, a new vertical (FBR-like)

reactor was erected and used

[26]

, which allowed synthesis of about 0.5 g/day of high-quality IF-

MoS

2

NP.

Figure 13.4A and B

shows typical scanning electron microscope (SEM) and transmission

electron microscope (TEM) images of such NP, respectively. The NP assume the form of oblate

structure having many (

20) closed walls and small hollow core. The diameter of such NP spans

.

in the range of 60

150 nm with mean value of about 80 nm. When added to lubricating fluids,

these NP were found to exhibit excellent tribological behavior

[27,28]

.

A more recent accomplishment was the synthesis of rhenium (Re) doped IF/INT NP

[29]

.

Rhenium, being one-column to the right of W (Mo) on the periodic table, has five valence electrons

in its outer shell compared to four for molybdenum or tungsten. Thus, substituting about 100 Re

atoms in the IF-MoS

2

nanoparticle (

10

6

atoms) induces negative surface charge on the nanoparti-

cle surface. Such NP behave quite differently from the undoped NP. For example, the doped NP

disperse well and form stable suspensions in various fluids. They also exhibit enhanced conductiv-

ity and may find electronic applications in the future. Most importantly, adding small amounts of

such NP to lubricating fluids (poly-alpha olephin: type 4, i.e., PAO-4) leads to a precipitous reduc-

tion in the friction and wear

[29,30]

as shown in

Figure 13.5

. These findings make the IF NP and

particularly the doped ones, very suitable for some medical applications, as explained below.

B

13.3.3

Self-lubricating surfaces

The idea of making self-lubricating surfaces, i.e., hard surfaces which do not require any fluid to

lubricate the contact area, is not new and has been pursued by many groups before; see for example