Biomedical Engineering Reference

In-Depth Information

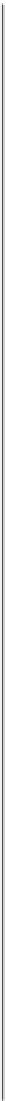

Table 11.1

Summary of Studies on Nanoparticle Applications in Materials Used in Orthodontics

Nanoparticle/

Nanoscale Imaging

Technique Used

Parameters

Evaluated

Material Studied

Results

Orthodontic stainless

steel wire

[13,14]

NiP film impregnated

with IF-WS

2

nanoparticles

(i) Frictional forces

measured on coated

and uncoated wires

(i) Reduced to 54% on

coated wires

(ii) Friction coefficient

(ii) Friction coefficient

reduced one-third from

0.25 to 0.08

Ni

Ti substrates

[15]

Cobalt and IF-WS

2

nanoparticles

Friction coefficient

66% reduction in coated

substrates

Stainless steel, beta-

titanium and Ni

AFM

Surface roughness

Surface roughness

influenced the effectiveness

of sliding mechanics,

corrosion behavior, and

esthetics

Ti

archwires

[10]

Stainless steel and

Ni

AFM coupled with

nanoindenter

Effects of

decontamination and

clinical exposure on

elastic modulus,

hardness, and surface

roughness

Decontamination regimen

and clinical exposure had

no effect on Ni

Ti archwires

[11]

Ti wires

but did have a statistically

significant effect on

stainless steel wires.

Decontamination of

stainless steel wires

significantly increased

surface hardness (P

5

0.01)

and reduced the surface

roughness (P

5

0.02)

Conventional stainless

steel, ceramic, self-

ligating stainless steel

and ceramic

brackets

[12]

AFM

Surface roughness

2-year orthodontic

treatment regime showed

that self-ligating ceramic

brackets had undergone

less change in roughness

parameters than self-

ligating stainless steel

brackets. Self-ligating

ceramic brackets exhibited

low friction and better

biocompatibility than other

brackets

Fuji II GIC

[16]

Nanohydroxy and

fluoroapatite, N-

vinylpyrrolidone (NVP)-

containing polyacids

CS, DTS, BFS

Highest values for CS,

DTS, and BFS were found

for NVP-nanoceramic

powder modified cements

(184 MPa for CS, 22 MPa

for DTS and 33 MPa for

BFS)

(Continued)