Biomedical Engineering Reference

In-Depth Information

0.35

0.3

0.25

0.2

0.15

0.1

0.05

0

0

5

10

15

20

25

30

35

Number of cycles

Uncoated wire

Ni-P + IF-WS2

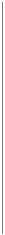

FIGURE 11.4

Friction coefficient of the orthodontic wire substrate compared to a wire coated with Ni

P and IF-WS2

[13]

.

IF-WS2. The coated wires were then analyzed by scanning electron microscope (SEM) and energy-

dispersive X-ray spectrometer as well as by tribological tests using a ball-on-flat device. Friction

tests simulating archwire functioning of coated and uncoated wires were carried out by an Instron

machine. The adhesion properties of the coated wires after friction were analyzed using a Raman

microscope. The frictional forces when measured on the coated wire were reduced by up to 54%

when compared to uncoated stainless steel wire. The friction coefficient was also significantly

reduced from 0.25 to 0.08 (

Figure 11.4

). These studies concluded that stainless steel wires coated

with these nanoparticles might offer a novel opportunity to substantially reduce friction during

orthodontic tooth movement. It has been reported in animal studies that these nanoparticles are bio-

compatible

[14]

.

Tungsten disulfide nanocoating has also been evaluated for friction reduction of Ni

Ti sub-

strates (

Table 11.1

). Ni

Ti substrates were coated with cobalt and IF-WS

2

nanoparticles film by

electrodeposition procedure and the friction test results showed up to 66% reduction of the friction

coefficient on the coated substrates when compared to uncoated substrates

[15]

. The results of such

studies may have potential applications in reducing the friction when using orthodontic Ni

Ti

wires. One drawback to the incorporation of Ni in these types of coatings is the potential for aller-

gic reactions in patients with nickel sensitivity

[20

P coat-

ings on stainless steel and Ni

Ti wires should be evaluated for biocompatibility in animal models

and further in human trials.

23]

. Therefore, the effect of such Ni

11.4

Nanoparticles in orthodontic adhesives

Composite materials and glass ionomer cements (GIC) have been primarily used in orthodontics as

adhesive agents for securing orthodontic brackets and bands to the surface of the teeth. The largest

application of nanoparticles has been in dental composite materials, where they have been used to