Biomedical Engineering Reference

In-Depth Information

6.2

Development of antibacterial nanocomposite with CaP nanoparticles

A spray-drying technique described previously

[49]

was used to make nanoparticles of ACP

(referred to as NACP). Calcium carbonate (CaCO

3

; Fisher, Fair Lawn, NJ) and dicalcium phos-

phate anhydrous (CaHPO

4

; Baker, Phillipsburg, NJ) were dissolved into an acetic acid solution to

obtain final Ca and P ionic concentrations of 8 and 5.333 mmol/L, respectively

[33]

. This resulted

in a Ca/P molar ratio of 1.5, the same as that for ACP (Ca

3

[PO

4

]

2

). This solution was sprayed into

a heated chamber, and an electrostatic precipitator (AirQuality, Minneapolis, MN) was used to col-

lect the dried particles.

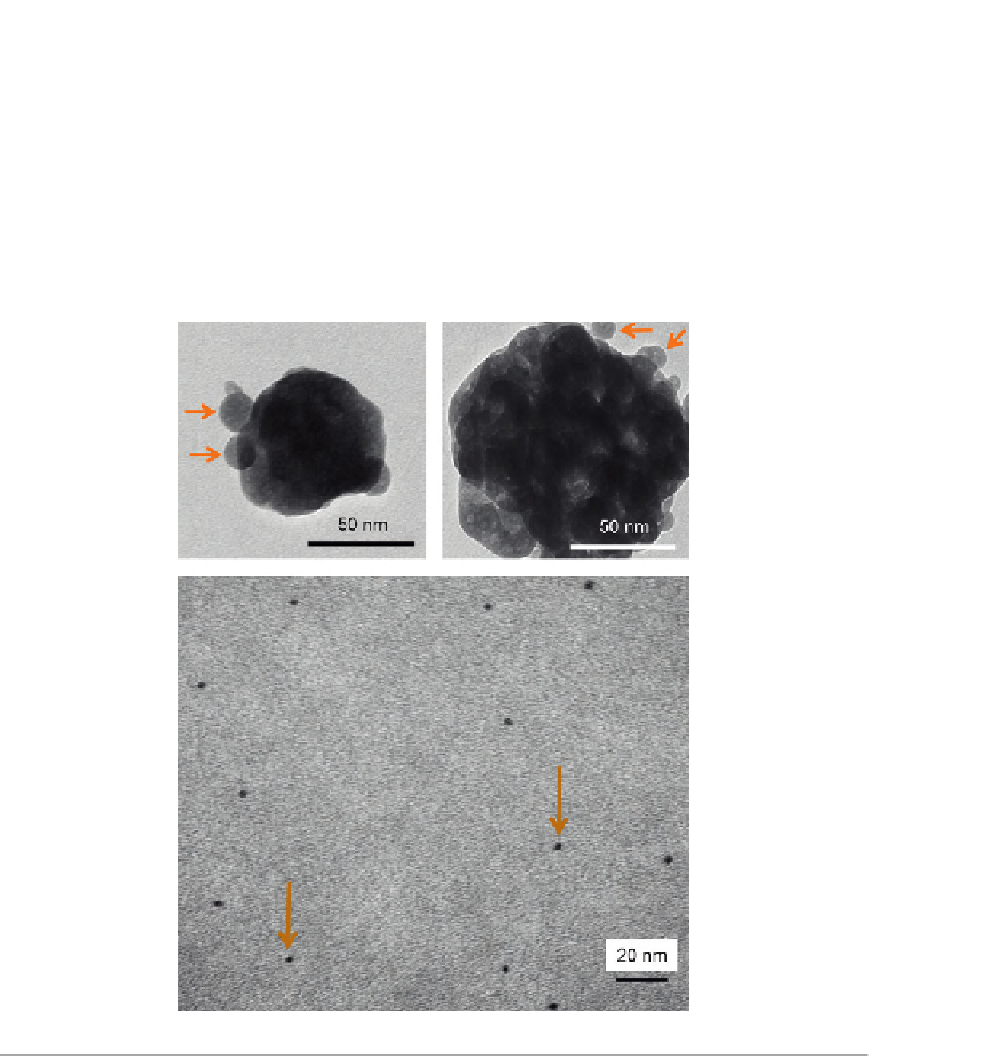

Figure 6.1A and 6.1B

shows transmission electron microscopy (TEM)

(A)

(B)

(C)

FIGURE 6.1

TEM micrograph of the spray-dried NACP: (A) small NACP and (B) NACP cluster. (C) TEM micrographs of

NAg in the resin matrix. The particle size was measured (mean

0.6 nm. Arrows

indicate the silver nanoparticles, which were well dispersed in the resin with minimal appearance of

nanoparticle aggregates.

sd;

n

5

100) to be 2.7

6

6

Adapted from Ref.

[21]

and

[50]

with permission.