Biomedical Engineering Reference

In-Depth Information

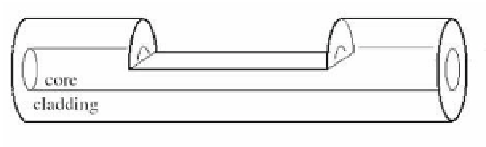

mechanism for this type occurs in the optical iber and energy is not

allowed to escape the iber to be recaptured. Therefore, this optical

iber not only acts as a signal transmission line, but also as a sensing

component. To improve the sensitivity of optical iber sensors for

use in iber optic biosensors, the iber must be processed a second

time by stripping a portion of cladding so the light-sensitive core

layer can be in contact with the sample solution. The area where

the cladding is removed is called an optical iber window, as shown

in Fig. 6.16. The iber has a window gap structure and the depth

of this gap can be controlled. A shallow depth would only require

the removal of the jacket layer, while a deeper depth allows the

iber core to be exposed. This section describes three methods to

fabricate optical iber windows: etching, polishing, and high energy

ultrashort pulse laser processing.

Figure 6.16

Schematic diagram of optical iber window.

6.4.1 EtchingMethod

The core of glass iber is fused silica. Fused silica is a noncrystalline

(glass) form of silicon dioxide (quartz, sand). To generate good

lat etching results, the BOE (Buffered Oxide Etch), rather than HF

(Hydroluoric Acid) is used to etch the optical iber [39] because the

BOE has lower etching rate. Besides, BOE etching is only effective

for SiO

2

, and the plastic coating covering on the D-shaped window

optical iber cannot be removed. Therefore, the etching length can be

determined by controlling the length of the bare iber, and the etching

depth can be determined by controlling the etching time. However,

the etching rate is dependent on the temperature and concentration

of the BOE. Thus, the etching temperature must be controlled if

accurate etching depth is required. For single mode optical ibers,

an etching depth of at least 50 μm must be obtained to let the

evanescent wave through. Before etching, part of plastic coating

must be stripped, followed by BOE etching for a properly controlled

etching time. The maximum etching time can be measured as the

Search WWH ::

Custom Search