Biomedical Engineering Reference

In-Depth Information

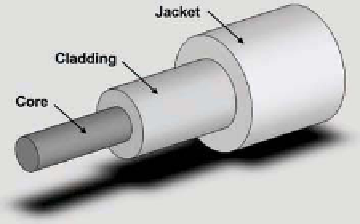

a cylindrical optical waveguide along its axis to radial, and

can generally be divided by its refractive index into 3 layers:

core, cladding, and the outside protection jacket. The core and

cladding of the optical iber transmit the basic elements of light.

Fiber optic sensors are not affected by electromagnetic noise

or magnetic interference. The impact of ionizing radiation can

also be avoided though the use of radiation treatment making it

suitable for demanding environments, such as nuclear power

plants. Also, since the iber optic sensors use the same iber as

both a sensor and signal transmission line, they can be placed in

areas that traditional sensors with wires could not, such as small

or not easily accessible locations. Fiber optic sensors use light as

the transmission medium rather than current or voltage, so there

is no risk of electric shock, making them suitable for medical

measurements. Fiber optic materials do not corrode, and are thus

suitable for deep-sea engineering and environments where there

is risk of chemical corrosion. Glass iber has a higher temperature

resistance gauge than metal, and longer-term stability and

fatigue resistance, making it suitable for long-term monitoring.

Since optical ibers have been used in long distance optical iber

communications, iber optic sensor technique is easily adapted to

long-distance telemetry. In addition, the use of wavelength division

multiplexing technique in optical communications also helped the

same optical ibers with multi-point measurement, which has lead

the iber optic sensors being widely used in aerospace, medicine,

chemistry, earth engineering, civil engineering, and other ields as

well.

Figure 6.15

Structure of an optical iber.

Fiber optic sensors rely on the measurement of physical

(chemical) content, hence, inding a mechanism to modulate the

Search WWH ::

Custom Search