Biomedical Engineering Reference

In-Depth Information

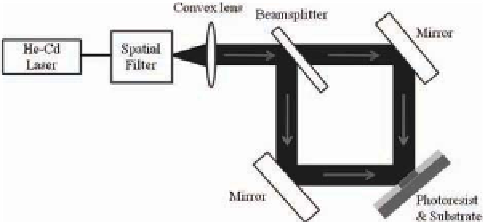

6.3.3 HolographicExposure

Holographic exposure uses the interference fringe pattern,

consisting of a set of equally spaced bright and dark lines, of two

intersected laser beans to expose the photoresist coated on a

substrate. The exposed photoresist is then chemically developed

to form a pattern of straight groves with a sinusoidal proile. The

developed photoresist with a pattern of straight groves can be used

as a master grating for replication, or as a mask for anisotropic

etching of the substrate. Due to the fact that optical masks are not

required in the fabrication processes, holographic exposure is also

considered one of the maskless lithography techniques. It is suitable

for fabricating gratings with high grove densities and large areas, and

is widely used in the fabrication of commercial gratings and actively

researched [23-28]. Holographic gratings, however, cannot be easily

blazed because of their sinusoidal grove proile, and their eficiency

is usually considerably less than a comparable ruled grating. Figure

6.10 shows the schematic diagram of the experimental facility

Figure 6.10

Schematic diagram of the experimental facility used for

holographic exposure.

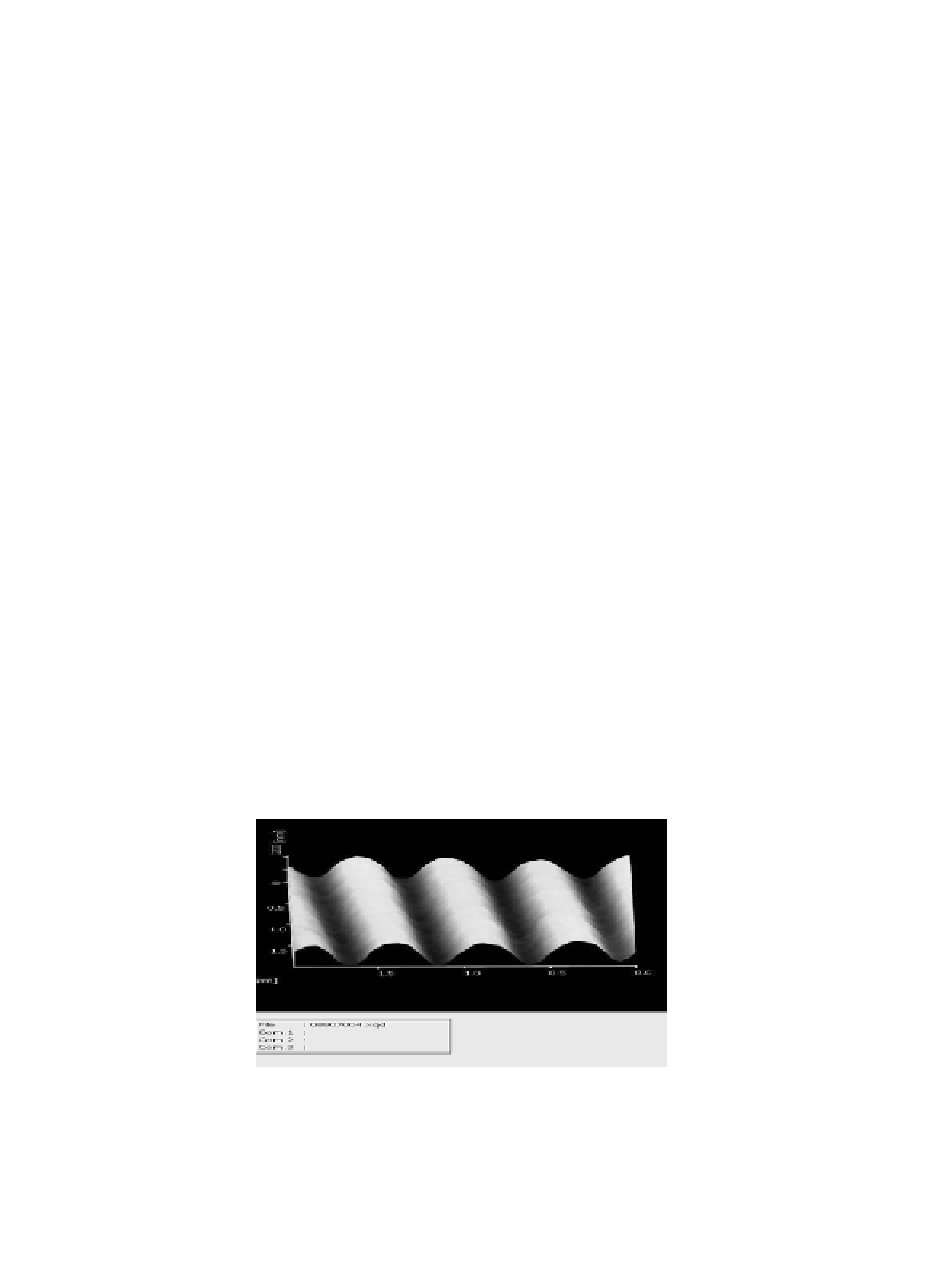

Figure 6.11

SEM image of a holographic grating with a grove density of

1800 groves/mm.

Search WWH ::

Custom Search