Biomedical Engineering Reference

In-Depth Information

been used as waveguide couplers and detectors [13-20]. In the

following, common fabrication methods of diffraction gratings are

discussed.

6.3.1 Diamond Ruling

Diamond ruling, using a carefully shaped diamond tool to

mechanically rule the surfaces of grating substrates, produced the

irst diffraction gratings made for commercial use, and now-a-days

continues to be widely used in producing various types of diffraction

gratings. Due to the ability in controlling the shape of the diamond

tool and thereby the shape of the ruled groves, diamond ruling

enjoys a dominant position as the major method of fabricating blazed

gratings. On the other hand, the linear motion of ruling machines

makes this method be used mostly for producing diffraction gratings

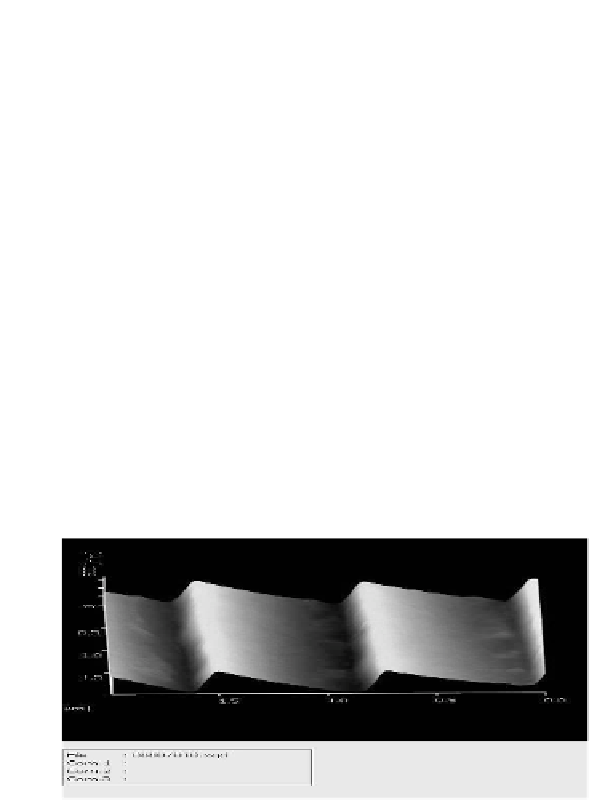

with straight groves. Figure 6.7 shows the SEM image of a planar

blazed diffraction grating (grove density: 1200 groves/mm, blazed

angle: 17.5°).

Figure 6.7

SEM image of a planar blazed diffraction grating.

6.3.2

Gray-Scale Lithography

In principle, gray-scale lithography adopts a gray-scale optical

mask to modulate the intensity of the light through it and exposes a

photoresist to different depths. After development, the photoresist

will form a three-dimensional proile corresponding to the intensity

pattern on the optical mask. The three-dimensional, developed

photoresist will then in turn be used as the mask for anisotropic

etching of the grating substrate. The fabrication processes are

Search WWH ::

Custom Search