Biomedical Engineering Reference

In-Depth Information

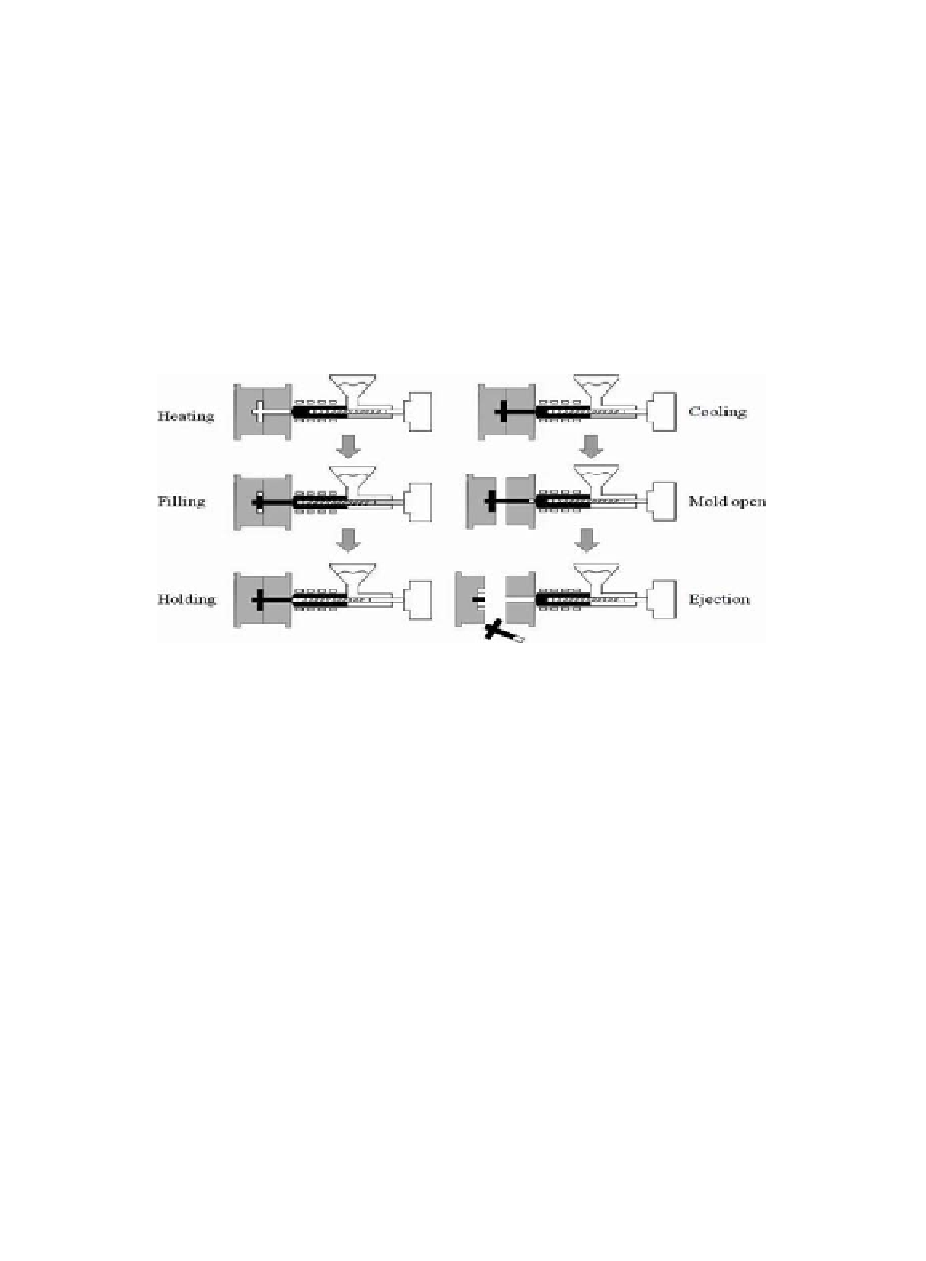

Micro-injection molding makes extensive use of thermoplastics,

but thermosetting plastics or ceramic materials are also used. The

main process of injection molding requires putting plastic granules

in a heating tube and heating them until they reach a liquid state.

Then a nozzle is used for high-pressure, high-speed injection of the

material, which passes through the sprue and runner to the mold to

be completed under pressure in the cavity. After cooling, the molded

object is released via the ejection system. The process includes

illing, packing, cooling, and other steps (as shown in Fig. 6.6). The

micro-injection molding technique provides the major advantage

of being able to produce reined, complex shapes in small-sized

inished products.

Figure 6.6

Micro-injection lowchart.

6.2.4

Bonding

The biosensor chip bonding technique is part of the manufacturing

process, but it can affect the overall accuracy of the most critical

aspect: a good and easy-to-operate interface. As such, the kind of

interface between the plastic polymers to construct the biosensor

chip by a bonding technique can be used as a basis for classiication.

It can be divided into two categories: attachable medium and non-

attachable medium. Bonding methods for the attachable medium

include the organic bonding medium, UV sensitive curable bonding

medium, or double-sided tape style. The non-attachable medium

uses fusion bonding for bonding. These bonding techniques can be

characterized as follows.

Attachable medium mounting/bonding technique: Bond

two plastic joints with organic dielectric [10] using appropriate

Search WWH ::

Custom Search