Biomedical Engineering Reference

In-Depth Information

A

B

C

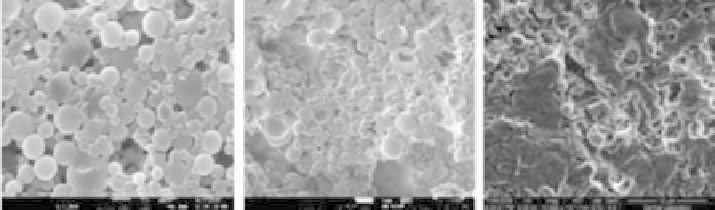

FIGURE 11.6

Changes. in. PLGA. nano-microsphere. morphology. with. the. drying. technique. used.. (A). Air. drying. (8500×)..

(B) Lyophilization.(8500×)..(C).In.vacuum.oven.at.50°C.(3000×).

In.this.speciic.case.air.drying.at.room.temperature.where.the.nano-microspheres.were.

obtained.in.a.dichloromethane-aqueous.phase.(5%.PVA).and.dried.at.room.temperature.

(RT). without. any. special. devices. was. determined. to. be. the. best. drying. technique.. This.

method.prevented.clustering.and.the.deformation.of.colloidal.particles.(Figure 11.6A).

The. size. of. the. nano-microparticles. was. examined. with. dynamic. light. scattering. and.

found.to.be.in.the.200.nm-9.µm.range.

PHBV. nano-microspheres. revealed. a. completely. different. morphology. than. PLGA.

(Figure 11.7),.even.though.the.size.range.was.very.similar,.in.the.350.nm-10.µm.range.

It.is.observed.that.the.surface.of.the.PHBV.nano-microspheres.is.mesoporous,.as.can.be.seen.

in.the.SEM..This.normally.is.not.a.desirable.feature.and.could.be.the.major.route.for.the.leakage.

of.entrapped.drug.from.the.nano-microspheres..On.the.other.hand,.it.could.be.an.advantage.in.

that.water-soluble.macromolecules.can.be.loaded.onto.these.micro-nanospheres.without.put-

ting.them.through.the.micro-nanosphere.formation.process..It.was.observed.that.the.extent.of.

the.porosity.of.the.sphere.surfaces.depended.on.the.HV.content.and.also.most.probably.on.the.

source.of.the.PHBV.(company,.microorganism.type,.puriication.approach,.etc.).

11.2.2.2.2 Preparation and Characterization of Nano-Microcapsules

Designed for Controlled Release Purposes

Nano-microcapsules.are.different.from.the.spheres.because.the.capsules.are.hollow.in.the.

inside,.while.the.spheres.are.full.

A

B

C

FIGURE 11.7

SEM.micrographs.of.spheres.prepared.from.PHBV.copolymers.with.5.and.8%.HV..They.were.also.of.different.

sources..(A).PHBV5.(HV.5%).(10,000×)..(B).PHBV8.(HV.8%).(3,000×)..(C).Magniication.of.B.