Environmental Engineering Reference

In-Depth Information

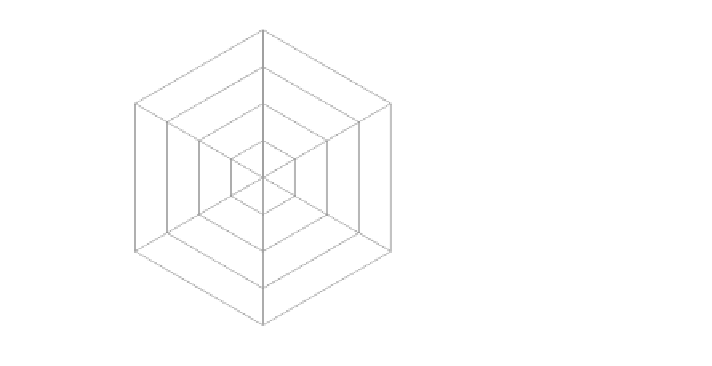

OP3

80%

60%

OP1

OP6

40%

20%

1

2

3

0%

OP4

OP5

Legend:

OPX -operator no X

1,2,3 -number of

production shift

OP2

Fig. 3

Visual inspection effectiveness for single operator in three shifts working system (own source)

Table 3

FPY index value

of quality effectiveness for

different operators working in

three shifts working system

and job experience range

(own source)

Operator

Job experience

(year range)

Average effectiveness

of operators in FPY (%)

Production shift

1

2

3

1-5

64

49

51

OP1

OP2

6-10

54

72

75

OP3

6-10

36

32

43

6-10

51

52

47

OP4

OP5

>15

55

62

45

OP6

>15

63

74

67

row better on night shifts (ex. OP2 and OP6). This diversity relates to unique human

biorhythm. This factor divides population of operators into subgroups characterized

with proper per hour work effectiveness during day and night. Unfortunately day

and night effectiveness of performed tasks is variable and also dependent on other

influencing factors. As an example can be listed situation context, daily mood, health

discomfort or musculoskeletal disorders. Impact of that additional factors is visible

in lower work effectiveness level. Additional (“disturbing”) factors make up risk

parameter and mostly appears sporadically and accidentally.

Paying attention to biological rhythm of operator activity already on stage of

recruitment for controller position enable to limit to possibly maximum extent

human errors appearance, especially failure of missed defects. Moreover ergo-

nomic work organization drawing attention not only to single operators biorhythm

but also to proper working conditions on work places should result in effectiveness

of visual inspection as well as other production processes increase.

Search WWH ::

Custom Search