Environmental Engineering Reference

In-Depth Information

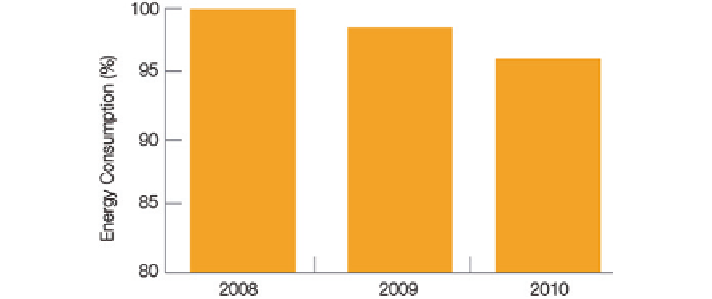

Fig. 6

Specific energy consumption of breweries in UE (adopted from Berkhout et al.

2013

)

3.4.1 Kompania Piwowarska

At all breweries of Kompania Piwowarska, electric and thermal energy consump-

tion is continuously monitored, which allows to identify the efficiency of the pro-

duction processes. Additionally, at the breweries in Tychy and Pozna´ constant

monitoring of fuel consumption in the boiler rooms is carried out, which, in turn,

enables to regularly estimate the size of CO

2

emission to the atmosphere. At the

same time, work connected with improvements in the technological processes and

modernisation of the existing systems never stops at all the premises.

These actions have led to a significant reduction in the energy intensity indi-

cators in recent years. The consumption rate of the thermal energy produced

per a unit of beer made at the brewery in Pozna´ has gradually fallen from the

value achieved in 2013 which was equal to 57.68 MJ of energy per hectolitre

of beer. In the case of the electric energy consumption, the global rate for the

entire Kompania Piwowarska was 5.84 kWh/hl of beer. The reference indicator

of electric energy intensity determined in Best Available Technology (BAT) for

the brewing sector ranges from 8 to 12 per hectolitre of beer. Therefore, the rate

accomplished by Kompania Piwowarska suggests a high degree of commitment to

limiting energy consumption in the production processes.

The use of renewable energy sources is mainly conditioned by technical

limitations and availability of the “clean” fuels. The technical conditions of the

brewery in Tychy allow to use renewable energy in the form of biogas produced

at the premises of the factory's sewage treatment plant. Biogas, due to its com-

position, is burnt together with natural gas. Application of this innovative solu-

tion brings both economical and environmental benefits. Wanting to decrease the

environmental burden, in 2006 Kompania Piwowarska eliminated the boiler room

burning coal that was exploited at the brewery in Pozna´ and replaced it with a

modern gas and oil boiler room. Thanks to the conversion of coal into gas and

oil, a considerable reduction in the emission of, among others, carbon compounds

Search WWH ::

Custom Search