Biology Reference

In-Depth Information

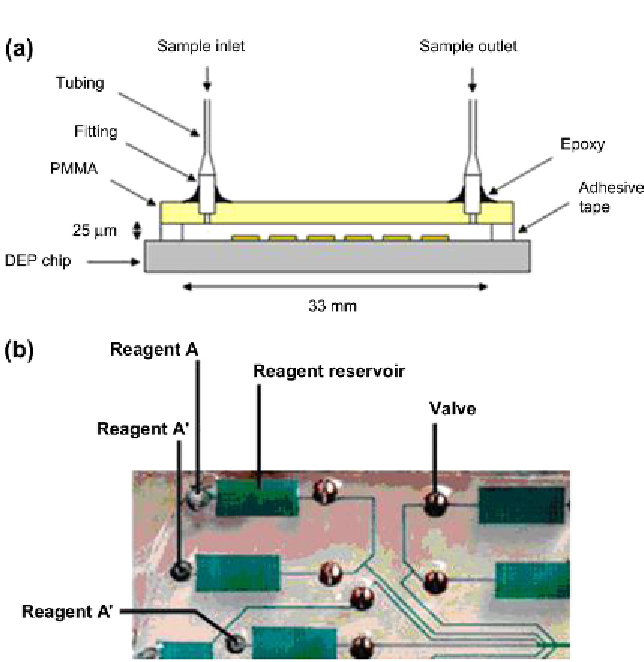

Figure 10.1

Illustration of microfluidic systems. (a) Cross-sectional schematic of a

microchannel. Source:

Reproduced from Ref.

2

. (b) Top view of a microfluidic network

of reservoirs, channels, and valves. Source:

Reproduced from Ref.

3

. (For color version of

this igure, the reader is referred to the online version of this topic.)

10.1.1. Microfabrication

Microfabrication techniques, developed for the microelectronics industry,

enable the creation of complex systems with dimensions down to tens of

nanometers in materials, such as silicon, glass, or metals. These techniques

include the patterning of substrates by lithography, the deposition of thin

films using evaporation, sputtering, or oxidation, and the removal of mate-

rial by etching or lift-off processes. Microfabrication is often expensive,

time-consuming, and requires clean room facilities. Since microfluidic sys-

tems generally have a larger footprint than microelectronic devices, this

means that the cost per device is high. Additionally, for some microfluidic

applications, the traditional microfabrication materials are not suitable.

1

Search WWH ::

Custom Search