Environmental Engineering Reference

In-Depth Information

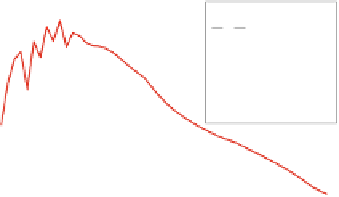

Fig. 4.80 shows not only the Hg species distributed along the height of furnace

chamber, it also shows the connection between the average temperature, the O

2

concentration and the Hg species distribution along the furnace. The black line is

the migration curve of Hg

0

. It shows that the Hg in the furnace mainly existed in the

form of Hg

0

. The figure also shows that, in the region from the low secondary air to

the furnace chamber's outlet, the Hg

0

distribution's overall trend decreased in the

burner region and then increased after the tertiary air region, then decreased again

from the deflection arch to the outlet region of the furnace. The rapid decrease in

Hg

0

near the burner area certainly led to the increase in Hg

2+

concentration, espe-

cially the generation of HgO. With the alternate injection of the primary air and

secondary air, the oxygen concentration was fluctuating from 0% to 3%. And with

the injection of the secondary air, the oxygen was fully supplemented, which in-

duced a small quantity of HgO generation. The highest concentration of HgO was

16.19%. When the flue gas left the burner area, the reactive oxygen component was

exhausted gradually, and the HgO generating amount decreased rapidly. Then the

HgO concentration remained low in part of the next region after the burner area.

When the flue gas went through the outlet region of the furnace, the temperature of

the flue decreased rapidly, so that it caused the HgO and HgCl

2

to generate again.

Apart from this we could also find that because the burner area (the furnace

chamber's elevation was 1267017355 mm) had obviously high-low alternate

temperature band areas, with the alternate injection of the primary air whose tem-

perature was lower, the combustion was further intensifying after the injection of

the secondary air, and the local temperature was increasing rapidly. The Hg form

distribution was largely affected by the frequent variety of the flue gas component,

especially the oxygen, of the burner region and the combustion condition.

Ox

yg

en (

%

)

100

1800

5

80

Hg

0

HgCl

2

HgO

O

2

Average temp.

1600

4

60

3

1400

40

1200

2

20

1

1000

0

800

0

10

15

20

25

30

35

40

Furnace height (m)

Fig. 4.80

Distribution characteristics of mercury species relative to furnace chamber height

Fig. 4.81 shows the Hg's component as percentage of each burner spout at the

burner region. It was found that at different heights of the furnace chamber, the Hg

speciation was slightly different. The Hg

0

concentration was relatively lower, and

Search WWH ::

Custom Search