Environmental Engineering Reference

In-Depth Information

Transformation in Flue Gas

temperature was close to 1,000 K, the final product was 2% Hg

0

, 20% HgCl, and

78% HgCl

2

[15]

. These values were higher than the predicted results in this section.

The difference could be attributed to the parameter options in the calculation and

the differences in experimental and calculation conditions in the current work.

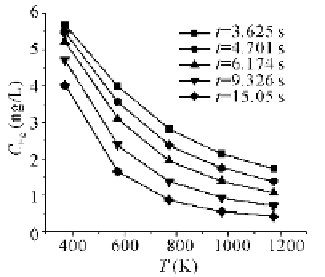

Fig. 4.56

Impact of temperature on Hg

0

oxi-

dization at 40 ppm HCl, residence time from

3.63 to 15.05 s

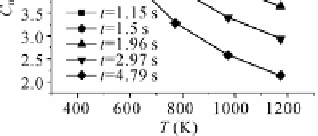

Fig. 4.55

Impact of temperature on Hg

0

oxidization at 20 ppm HCl, residence time

from 1.15 to 4.79 s

Fig. 4.57 and Fig. 4.58 present the impact of residence time on the transforma-

tion of mercury speciation with the reaction conditions of 6.478 g/m

3

Hg

0

inlet

concentration, 60 or 20 ppm HCl concentration, and 3731173 K reaction, respec-

tively. When all other conditions were unchanged, the increase in gas residence time

decreased the amount of Hg

0

. It meant that a longer retention period increased the

oxidation of Hg

0

, and that mercury oxidation in flue gas usually was far from a

theoretically balanced state because residence time was usually less than reaction

time in theory.

Fig. 4.58

Impact of residence time Hg

0

oxi-

dization at 20 ppm HCl, temperatures from

373 to 1173 K

Fig. 4.57

Impact of residence time Hg

0

oxidization at 60 ppm HCl, temperatures

from 373 to 1173 K

Fig. 4.59 and Fig. 4.60 present the impact of Hg

0

inlet mercury concentration on

the transformation of mercury speciation with the reaction conditions of 20 or 80

Search WWH ::

Custom Search