Environmental Engineering Reference

In-Depth Information

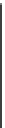

Hg

(g)

in flue gas decreased greatly; however, the Hg

p

concentrations in flue gas

increased by 22% and 18%, respectively.

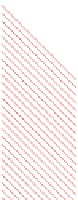

70

Particulate mercury

Gaseous mercury

60

50

40

30

20

10

0

No.1

No.2

Fig. 4.11

Ratio of Hg

(g)

and Hg

p

in No. 1 and No. 2 conditions

80

Particulate mercury

Gaseous mercury

70

60

50

40

30

20

10

0

No.3

No.4

Fig. 4.12

Ratio of Hg

(g)

and Hg

p

in No. 3 and No. 4 conditions

The mercury concentrations per unit mass (μg/g) in coal, fly ash, and bottom ash

under different working conditions are presented in Table 4.3. Mercury concentra-

tions in coal were 0.2977 and 0.3911 μg/g, respectively, and those in fly ash ranged

within 0.2569 - 0.3315 μg/g. Meanwhile, the mercury concentration in the bottom

ash ranged within 0.0192 - 0.0362 μg/g. The concentration of mercury in the bot-

tom ash was much lower than that in coal because most of the mercury evaporated

into gas at the high combustion temperature. Mercury concentration in the fly ash

was much higher compared with the bottom ash, which was different from other

major metal trace elements. This difference can be attributed to the relatively lower

temperature environment of the tail flue gas. Mercury vapor condensed on, or was

adsorbed by, the surface, thus increasing mercury concentration in the fly ash. The

mercury concentration in the fly ash can potentially pollute water and soil.

Search WWH ::

Custom Search