Environmental Engineering Reference

In-Depth Information

8

14

7

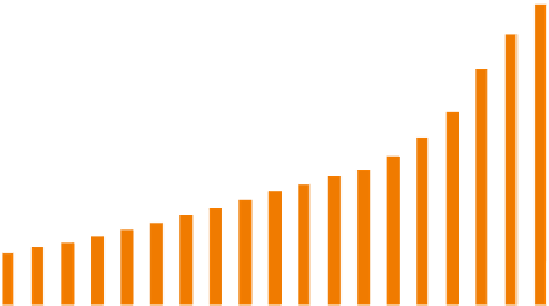

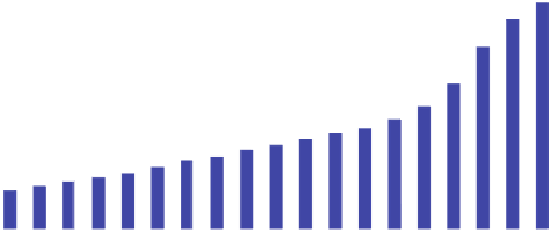

Total installed capacity of power

12

6

Total installed capacity of coal-fired power

10

Total coal consumption of coal-fired power

5

4

8

3

6

2

4

1

2

0

Year

Fig. 1.2

Capacity and coal consumption of electric power generation in China from 1990 to 2008

Conventional pollutant emission control technologies for particles SO

2

and NO

x

has progressed in recent years in China. Currently, most coal-fired power plants are

equipped with dust-cleaning equipment

ˈ

such as electrostatic precipitators (ESP) or

fabric filters (FF). Desulfurization technology has also rapidly developed

[8]

. In

2005, the capacity of coal-fired power plants equipped with a desulfurization unit

was 12.3%. However, in 2009, this capacity was about 78% (about 470.0 GW). In

addition, SO

2

emissions from coal-fired power plants appeared to have decreased

for the first time. Wet limestone-gypsum desulfurization is mainly used as flue gas

desulfurization technology in China. By 2007, 26 sets of flue gas NO

x

-controlled

devices had been installed in coal-fired power plants in China, with a total capacity

reaching 11,250 MW. Most power plants used selective catalytic reduction (SCR)

technology, except four units of 600 MW that adopted selective non-catalytic re-

duction (SNCR). At present, nearly 200 sets of NO

x

-controlled devices for 105.0

GW capacity have passed environmental assessments

[9]

. Given the rapidly in-

creasing demands for environmental protection requirements, more coal-fired units

must be equipped with flue gas desulfurization and NO

x

-controlled devices.

However, although these conventional pollutant control technologies can affect

gaseous mercury (Hg

(g)

) emissions, the ability to control Hg

(g)

depends on mercury

speciation.

Search WWH ::

Custom Search