Agriculture Reference

In-Depth Information

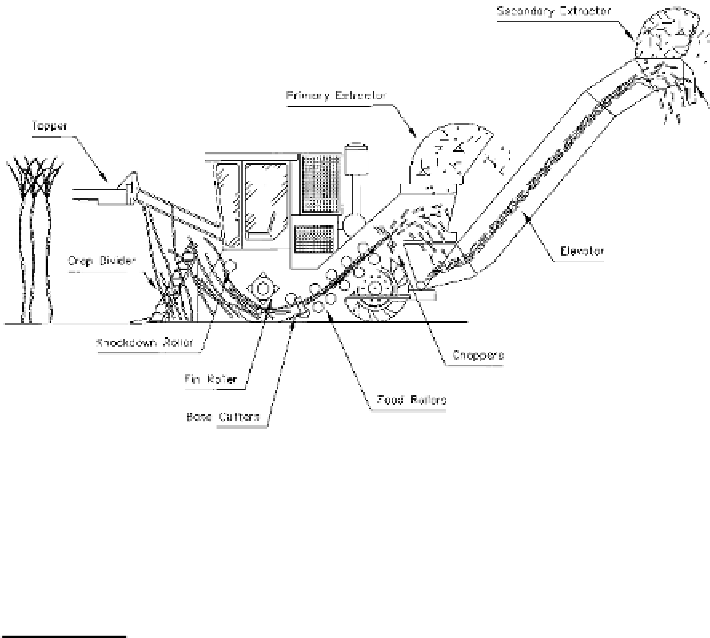

Fig. 5.34

Functional components of a sugar cane chopper-harvester. Adapted from [

27

]

Table 5.5

Field capacities (ha h

−1

) and throughput rates (Mg h

−1

, wet basis) for different mower-

conditioners for sorghum as affected by the harvest time

a

Early August Late August October November January

ha h

−1

Mg h

−1

ha h

−1

Mg h

−1

ha h

−1

Mg h

−1

ha h

−1

Mg h

−1

ha h

−1

Mg h

−1

MacDon Auger 1.78 76.9 1.55 83.7 0.88 56.8 0.99 59.6 1.88 58.7

MacDon Disk 2.03 90.2 1.72 88.0 1.01 62.1 0.67 48.2 2.57 73.4

Deere Tri- Lobe

Harvest

1.85

77.3

1.32 64.7 1.41 87.1

NA

NA 0.63 21.5

Deere Flail

1.92 74.8 1.20 60.2 1.10 65.2

NA

NA 0.91 NA

a

Adapted from [

29

]

[

29

]. The field efficiencies for the mower-conditioners can be reduced due to machine

plugging and crop build-up in front of the header. Poor windrowing (presence of

longer stems) also reduces baling capacity. The baler field capacity is much lower

compared to the mower-conditioner (Table

5.6

). The theoretical cut length and mois-

ture content also affects the self-propelled forage harvester performance (Table

5.7

).

5.4.3.6

Energy Cane Harvesting

Energy cane can be harvested green similar to sugar cane or harvested dry similar to

hay. Typically, green energy cane harvesting is similar to sugar cane harvesting

along with other field operations. The other alternative is to harvest energy cane

similar to hay. It consists of mowing green crop with rotary mowers capable of cut-

ting5-to6-mtallplantswith2-to4-cmdiameterandconditioning.Athroughput

Search WWH ::

Custom Search