Agriculture Reference

In-Depth Information

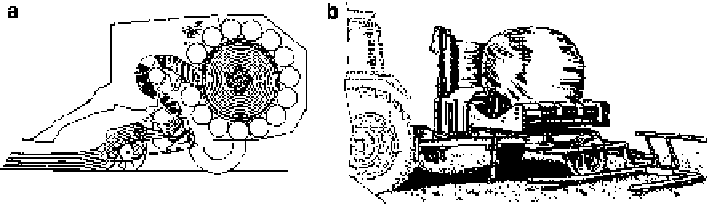

Fig. 5.16

(

a

) Round baler specifically designed for bales to be wrapped; (

b

) a wrapping machine

in operation. (

a

) Shows presence of a dual chopper and feeding of the chamber from the top.

Adapted from [

21

]

Large Square Baler

Rectangular balers offer better performance than round balers because they can con-

tinue to operate when releasing a bale compared to the round balers which stop when

releasing the bale. In addition, square bales are convenient to stack and transport.

The large square bale size and density (see Fig.

5.13

) are optimized for transport.

Typicalbalesizeisabout0.9×1.2×2.4m,andbulkdensityis150-230kgm

−3

. Like

round balers, rectangular balers are also towed by the tractor. A pickup head gathers

windrowedbiomassandfeedsittoachopperunit.Well-conditionedwindrowsare

smaller and easier to pick up [

2

]. Figure

5.17

shows a well-conditioned and a poorly

conditioned windrow. The poorly conditioned windrow on the left was difficult to

pick up compared to the well-conditioned windrow on the right [

19

]. The chopper

unit is equipped with crop processing knives to reduce the size of the material being

baled. In modern large square balers, biomass from the pickup is first gathered in a

pre-compression chamber. It accumulates to a designated pressure before being

pushed into the bale chamber by an electronically triggered stuffer fork (Fig.

5.18

).

Optimal baler throughput is obtained when enough hay is entering the chamber to

produce around one stuffer stroke for each stroke of the main plunger. The baler's

monitor indicates the ratio of stuffer to plunger strokes so that the operator can main-

tain optimal performance. The re-expansion of hay in the bale chamber is prevented

by fixed wedges and spring-loaded dogs. Square balers maintain the structure of

each bale by wrapping it with twine which must be cut and knotted in each bale.

5.3.4.2

Stack Wagons

Stack wagons consist of a rectangular compression chamber, with vertical sheet

metal side walls, and a mobile canopy on top which acts as a compression element.

Typically, a flail-type pickup harvests the crop which is conveyed into the chamber

bypneumaticmeans.Thestacksareverylarge(1-6 t),andtheworkratesvaryup

to10-15th

−1

. Figure

5.19

shows a self-loading wagon.

Search WWH ::

Custom Search