Agriculture Reference

In-Depth Information

a

b

ALFALFA

MAIZE

35

30

9 mm

7 mm

80

12 mm

5 mm

70

3 mm

25

60

20

50

8

15

25

15

10

mm

40

30

50

90

130

CAPACITY (t/h)

170

210

250

150

200 250 300 350 400

CAPACITY (t/h)

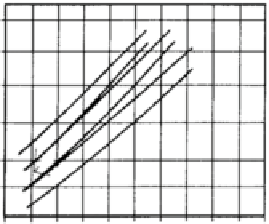

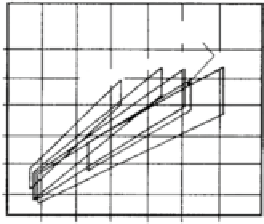

Fig. 5.12

Power required at PTO and capacity as affected by cutting length for alfalfa (

a

) and

maize (

b

). Adapted from [

21

]

• Row crop: Row-crop heads are usually used to harvest corn or sorghum and are

generally available in one to six row sizes and with different row widths. The

gathering chains or belts grab the cut stalks and feed them into the feed rolls.

The belts are more efficient in the lodged crops. Some row-independent heads

are also available, which permit harvesting independent of row width and they

are also effective for the lodged crop.

• Ear-corn snapper: Ear-corn snapper heads are similar to corn heads for combines

and are equipped with two counter rotating rolls which pull stalks through snap-

ping bars under the gathering chains to snap off the ears. Gathering chains carry

the ears back to a cross auger which conveys corn to the cutterhead for chopping.

The energy consumption is dependent on the crop and its dry matter content,

length of cutting, sharpness of the knives, and distance between the knives and fixed

shearbar.Typicalenergyrequirementvariesfrom2to3.0kWht

−1

. The PTO power

requirement as affected by the cutting length is shown in Fig.

5.12

.

5.3.4

Collection and Densification

After biomass is cut or chopped, an important process that follows is collection and

densification. For dry energy crops, baling is the most common method of densifica-

tion. For chopped biomass, processes of either cut-and-throw or cut-and-blow are

typically employed.

5.3.4.1

Baling

Balers are designed to produce either round bales or rectangular bales. The size of

rectangular bales falls into small and large categories. For bioenergy crops, large

rectangular balers or large round balers are most commonly used. Round bales are

Search WWH ::

Custom Search