Agriculture Reference

In-Depth Information

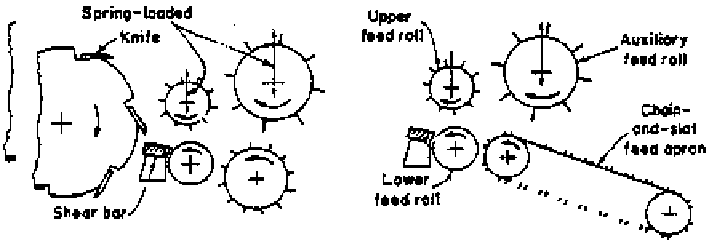

Fig. 5.9

Two types of feed mechanisms for a forage harvester. Adapted from [

16

]

Fig. 5.10

Flywheel (

left

) and cylinder (

right

) type cutterhead. Also shown are the main knife

shapes (

top

) employed in the cylinder cutterheads. Adapted from [

21

]

The base machine consists of a feeding mechanism (Fig.

5.9

) and cut-and-throw

cutterhead (Fig.

5.10

). The cut crop passes through the feed rolls, which consist of

four to five rollers mounted on top of each other. The upper rolls are spring loaded

to adjust the gap depending on the incoming biomass feed rate whereas the lower

rolls are generally fixed. The lower front and upper feed rolls generally have deep

flutes to firmly grip the biomass mat at all times. On the other hand, the lower rear

roll is generally smooth to avoid biomass being caught and dropped on the ground.

To clear jamming, provision to reverse the direction of rotation of feed rolls is often

provided. The biomass feed rate is varied by changing the roller speed. The feeding

mechanism may also incorporate metal-detection systems.

The cutterhead is the most significant component of a forage harvester. It deter-

mines the capacity, efficiency, and quality of cutting. These interlinked parameters

depend on the shape and condition of the knives and the stationary knife or shear bar.

Search WWH ::

Custom Search