Agriculture Reference

In-Depth Information

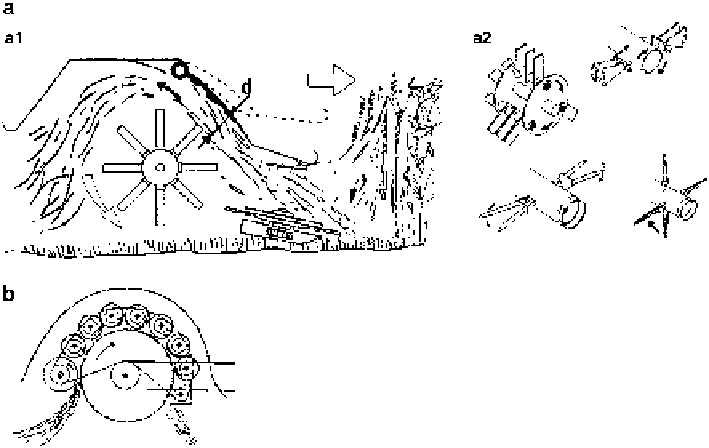

Fig. 5.7

(

a

) Flail conditioner can vary performance by changing the distance (

d

) between the flails

and peripheral housing (A

1

) or using different flails (A

2

). (

b

) Mat conditioning system: forage is

treated more rigorously due to differences in the peripheral speed of the central big drum and the

peripheral small drums. Adapted from [

21

]

rotating tines or brushes to scratch the plant cuticle. A curtain is used to guide the

cut crop to the impeller conditioner.

Roller conditioners pass the crop between rollers to crimp or crush the crop. The

rollers are mounted parallel to the cutter bar. Roller conditioners are used to condi-

tion both chopped stalks and whole stalks. The intensity of conditioning depends on

the construction of the two rollers, which can be metal, rubber coated, smooth, cor-

rugated, or grooved (Fig.

5.8

).Conditioningeffectivenesscanbeimprovedbyoper-

atingtherollersatslightlydifferentperipheralspeeds(0.5-10 %).Thelower

clearance between two rollers also increases effectiveness of conditioning. For uni-

form and effective conditioning, the width of the conditioners should be comparable

to the cutting implement. The diameter of conditioning rollers generally ranges

from170to220mm,whilethespeedrangesfrom700to1,200rpm.

Energy grasses like Miscanthus and switchgrass are harvested when the crop

moisturecontentistypically10-15 %,thuseliminatingtheneedforielddrying.

However, conditioning is done to facilitate pickup by the baler. The rubber rollers

are more suitable for thin-stemmed crops like switchgrass, while steel rollers are

more suitable for thick-stemmed crops such as Miscanthus. The amount of condi-

tioning depends on moisture content of crops, subsequent equipment needs, and

crop being harvested. For example, heavy conditioning of Miscanthus stems is nec-

essary to break the stems into smaller pieces to avoid choking the baler because of

an uneven feed of material.

Search WWH ::

Custom Search