Agriculture Reference

In-Depth Information

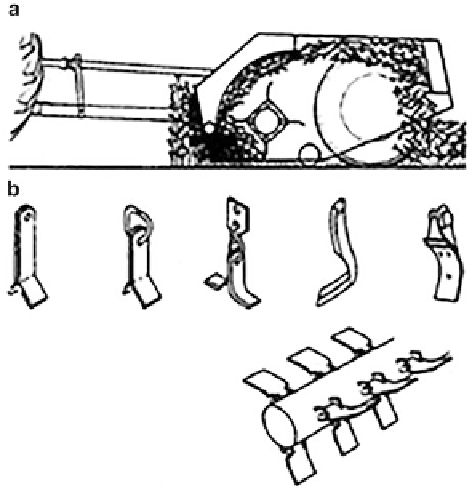

Fig. 5.6

A flail mower,

showing (

a

) side view and

(

b

) types of flails commonly

used and their arrangement.

Adapted from [

15

]

The main sources of losses in flail mowers are uneven stubble heights and recut-

ting of the crop. The recutting of plant makes it difficult to be picked up. A push bar

in front of the mower reduces the losses by bending the crop away from the

machines. This action pushes the upper portion of plant stems out of the path of the

blade and thereby reducing the losses by eliminating recutting. The push bar also

puts pressure on the stems, which immobilizes them and allows cutting at a lower

velocity. The higher power requirements are due to friction of rotating parts, impact

cutting, and air pumping as crop is conveyed [

16

]. Horizontal axis mowers are now

falling into disuse due to poor cut quality. However, vertical axis mowers are becom-

ing popular due to their higher ground speed (see Table

5.3

), robust construction,

and low maintenance requirements.

5.3.2

Conditioning

Conditioningisanoperationdesignedtoielddryhigh-moisturecrops.Various

conditioning methods, such as mechanical, chemical, and thermal, have been evalu-

ated for forage crops [

22

]. In mechanical conditioning, impellers or rollers are used

to crimp (Fig.

5.7a

) or crush the cut plants (see Fig.

5.7b

). The plant crushing or

crimping facilitates the moisture evaporation. Impeller or flail conditioners and

roller conditioners are the two main kinds of mechanical conditioners. Impeller

conditioners are used to condition whole stalks of a crop whereas rollers are used to

condition both whole stalks and chopped biomass. Impeller conditioners use

Search WWH ::

Custom Search