Agriculture Reference

In-Depth Information

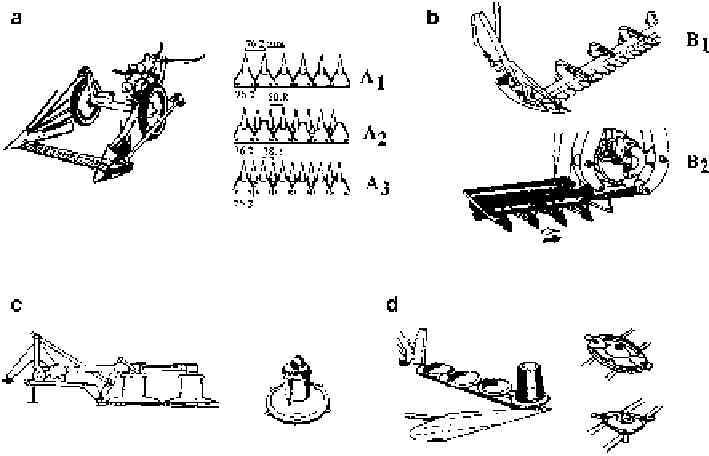

Fig. 5.5

Different mower solutions: (

a

,

b

) cutter bars and (

c

,

d

) rotary mowers. (

a

) Single cutter bars

with different finger intervals (A

1

, A

2

, A

3

); (

b

) double oscillating cutter bars: double knife bars with-

out fingers (B

1

) or one cutter bar and one finger bar moving in opposition (B

2

); (

c

) two drum mower

with top drive; (

d

) disk mower can have several disks with two or three knives. Adapted from [

21

]

plant's stem and its neighbors. There are two types of vertical axis rotary mowers:

disk and drum. Drive mechanisms in disk mowers are located beneath the cutting

blades to facilitate the cut crop flow through the machine. It also reduces energy

required in crop conveyance. Blades may be counter rotating to leave the cut mate-

rial in distinct bands or corotating for uniform distribution across the cutting width.

Drum mowers have their drive mechanism above the cutting blades. The cut crop

passes through the narrower spaces between or under the drums, which increases

energy required in crop conveyance.

5.3.1.3

Horizontal Axis Rotary Mowers or Flail Mowers

Flail mowers are used in “direct-cut” harvest operations to cut and condition forage.

Cuttingisaccomplishedbyfreelypivotingbladesattachedtoahorizontalrotating

drum (Fig.

5.6

). Flail mowers employ impact cutting mode. The cut crop is condi-

tioned and conveyed as it passes over the high velocity cutting blades. Forage can be

collected directly behind the mower or allowed to drop into the field for wilting. In

general, flail mowers tend to be less precise than the sickle or disk mowers. The crop

lossesareabout10-15%higherthanothermowersforstandingcrops[

16

].Conversely,

flail mowers perform better than sickle and disk mowers in highly lodged crops.

Because of this, they are ideal for harvesting energy grasses after overwintering.

Search WWH ::

Custom Search