Geology Reference

In-Depth Information

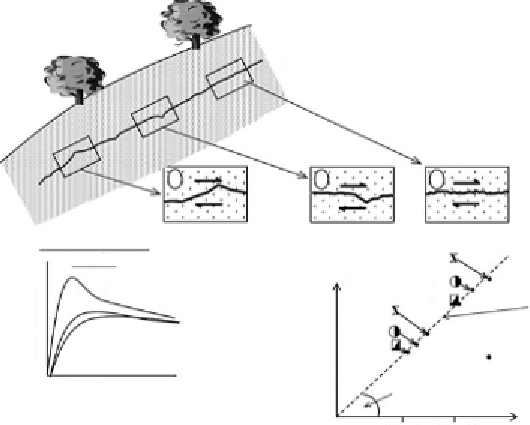

Figure 5.22

Methodology for

selecting a series of

samples of rock

joint, testing and

basic friction angle

for the naturally

textured rock joint

(after Hencher

et al., 2011).

natural joint with three

sampling points

A

B

C

direct shear

samples

Tests on 3 different

samples

A

2

peak strengths

Graphs for same normal

stress, σ in each test)

B

2

C

2

A

strength envelope for

non-dilating joint

B

A

1

B

1

C

1

C

= strength corrected

for dilation

basic friction

angle,φ

b

disiplacement

SampleA is roughest and therefore

dilates the most and has the highest

measured strength

Stage 1

Stage 2

normal stress, σ

tests on a series of samples from the same joint set (with similar surface

mineralogy and textures) provide a reasonably well-de

ned dilation-

corrected strength envelope, as illustrated in

Figure 5.22.

That strength

is frictional (obeys Amonton

is laws) and comprises an adhesional

component plus a non-dilational damage component that varies with

texture and roughness.

Barton (1990) suggested that the dilation-corrected basic friction

angle might be partly scale-dependent, as assumed for the asperity

damage component in the Barton-Bandis model (Bandis et al.,

1981), but further research using the same testing equipment as

Bandis but with better instrumentation, indicates that this is unli-

kely (Hencher et al., 1993; Papaliangas et al., 1994). Dilation-

corrected basic friction is independent of the length of the sample.

Scale effects do need to be taken into account in design but as a

geometrical consideration when deciding on an appropriate

'

eld

scale i° value.

Many silicate rocks are found to have a basic friction

40 degrees

(Papaliangas et al., 1995), and Byerlee (1978) found the same strength

envelope (

ϕ

≈

b

τ

σ

) for a large number of direct shear tests on various

rock types where dilation was constrained by using high con

= 0.85

ning

stresses. Empirically, it seems to be about the highest value for basic

friction achievable for natural joints in many silicate rocks and applic-

able speci

cally to joints that are forced to dilate during shear or where

dilation is suppressed because of the high normal load. Conversely,

much lower friction angles can be measured for natural

joints