Graphics Programs Reference

In-Depth Information

Using a Linear Hole Placement

Linear hole placement requires selecting a face on which to place the hole. Once

you've done that, you can simply click OK to generate the feature. You can also

click one or two edges to locate the hole relative to them using parametric dimen-

sions placed for you.

1.

Make certain that the 2013 Essentials project file is active, and then

open

c07-07.ipt

from the

Parts\Chapter7

folder.

2.

Start the Hole tool by selecting it from the Modify panel on the 3D

Model tab. It is also on the marking menu.

3.

Set the hole class to Counterbore. Set the hole type to Clearance

Hole, and then set the standard to be ANSI Metric M Profile. Set the

fastener type to Socked Head Cap Screw, and set the size to M4 and

the termination to Through All.

4.

Click the top face of the plate near the notch.

5.

Click the edges shown in Figure 7.11, and set their offset values to

14 mm.

6.

Click OK to place the hole.

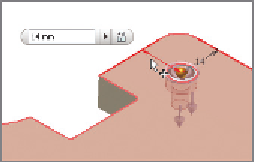

FIGURE 7.11

Placing the hole

based on the edges of the part

The diameter and depth of the counterbore and the size of the hole were all

determined based on standards for the fastener that will go through it. With the

hole in place, you can replicate it using the Rectangular Pattern tool.

Creating a Rectangular Hole Pattern

Let's create a series of these holes. On this part, the holes will be in a pattern where

the two directions are perpendicular, but the pattern can go in any two directions.

Certification

Objective

1.

Make certain that the 2013 Essentials project file is active, and then

open

c07-08.ipt

from the

Parts\Chapter7

folder.

Search WWH ::

Custom Search