Information Technology Reference

In-Depth Information

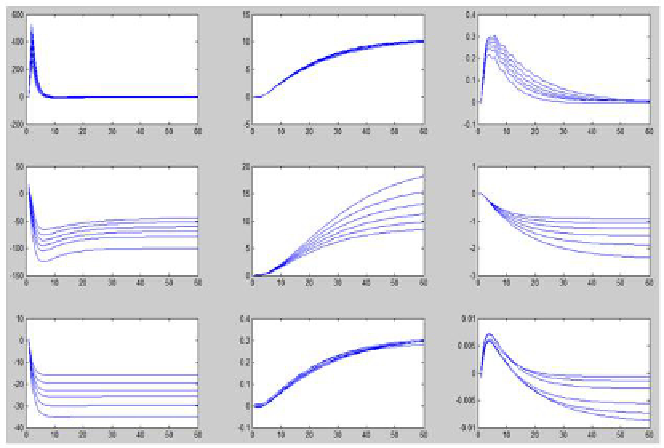

Fig. 3.

piecewise step response models at different load point of Ultra-supercritical

unit

simulation environment. MV1, MV2, MV3 represents the governor valve open-

ing, the fuel flow and the water flow respectively. CV1, CV2, CV3 represents

the load, the steam temperature and the steam pressure respectively. Load is

constrained by setpoint control while steam temperature and steam pressure is

constrained by zone control. Figure 4 and Figure 5 showed the manipulated vari-

ables and controlled variables in simulation when load changed from 1000MW

to 900MW. In Figure 4, the red curve, orange curve and blue curve represented

the governor valve opening, the water flow, the fuel flow respectively. In Figure

5, the red curve, orange curve, blue curve represented the load, steam pressure

and steam temperature respectively. Figure 6 was the figure of change of load.

Figure 7 was the figure of change of the steam temperature. Figure 8 and Figure

9 showed manipulated variables and controlled variables respectively when the

load changed from 600MW to 700MW.

The results show that the value of CV could rapidly track the expected value

of CV in the process of changing load and the setpoint control was accurate in the

steady working condition. The load could be changed by the rate of 20-30MW

per minute. Steam pressure smoothly rose and dropped following load. Steam

temperature fluctuated in the range of 1 degrees around of setpoint 599. The

system could guarantee good static and dynamic performance. So the multiple

models MCPC with double-layer structure is a promising method for coordina-

tion control of Ultra-supercritical unit.

Search WWH ::

Custom Search