Biomedical Engineering Reference

In-Depth Information

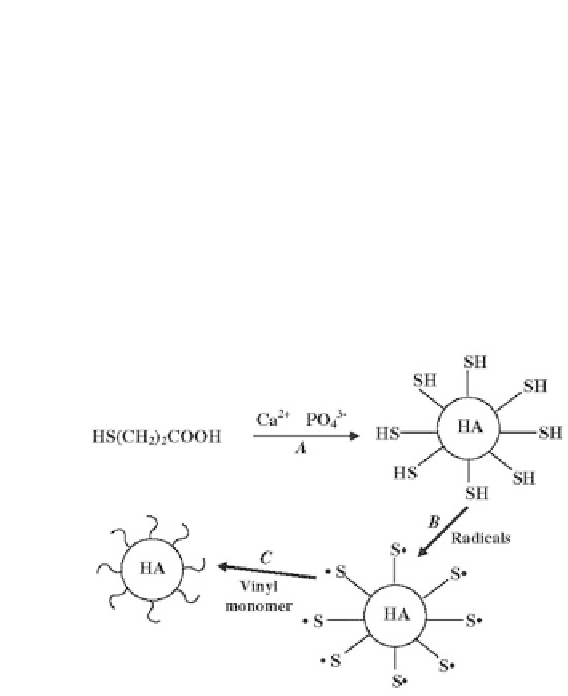

the sulfur-centered radicals on the HA surfaces (Fig. 6.8B), which

initiated the surface grafting polymerization of ethylene glycol

methacrylate phosphate (Fig. 6.8C) [1154]. Other examples might

be found in literature [144, 509, 510, 656, 1147-1153]. In general,

the purpose of surface modifying is not only to guarantee the even

distribution of calcium orthophosphate particles at a high loading

level in the matrix but also to prevent or delay the debonding process

of calcium orthophosphate particles from the matrix. Obviously, all

surface modifiers must satisfy several biomedical requirements,

such as no toxicity, good biocompatibility and no changes in the

biological or physico-chemical properties of the fillers.

Figure 6.8

Surface modification of HA particles by grafting polymerization

according to Lee et al. [1154]: (A) surface thiol functionalized

HA, (B) sulfur-centered radical on HA surface, (C) surface

grafting polymerization of ethylene glycol methacrylate

phosphate. Reprinted from Ref. [99] with permission.

Addition of adhesion-promoting agents might be an alternative

to improve the interaction between the fillers and the matrix.

For example, Morita et al. incorporated 4-methacryloyloxyethyl

trimellitate anhydride to promote adhesion of the polymer to HA

[1155]. In another study, phosphoric ester was added to the liquid

component of the formulation [1156]. Both the strength and the

affinity index of biocomposites were found to increase, probably due

to the effects of co-polymerization.

Possible interactions between BCP and HPMC have been

investigated in IBS composites [900, 901, 1157]. After mixing, there

Search WWH ::

Custom Search