Biomedical Engineering Reference

In-Depth Information

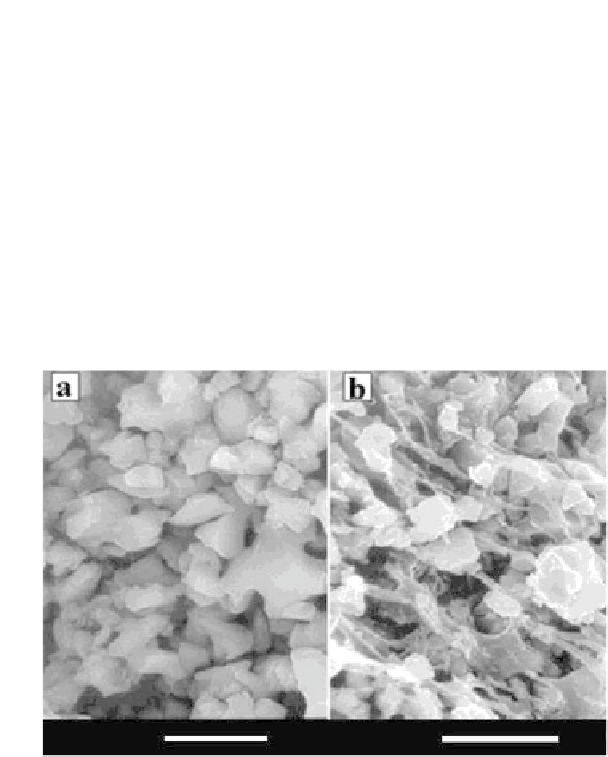

Durucan and Brown [53, 393, 394]. The authors prepared CDHA/

PLA and CDHA/PLGA biocomposites by solvent casting technique

with a subsequent hydrolysis of α-TCP to CDHA in aqueous solutions.

The presence of both polymers was found to inhibit α-TCP hydrolysis,

if compared with that of single-phase α-TCP; what is more, the

inhibiting effect of PLA exceeded that of PLGA [53, 393, 394]. The

physical interactions between calcium orthophosphates and poly(α-

hydroxyesters) might be easily seen in Fig. 6.2 [53]. Another set of

good pictures might be found in Ref. [87]. Nevertheless, it should not

be forgotten that typically non-melt based routes lead to development

of composites with lower mechanical performance and many times

require the use of toxic solvents and intensive hand labor [178].

Figure 6.2

SEM micrographs of (a) α-TCP compact; (b) α-TCP-PLGA

biocomposite (bars = 5 µm). Reprinted from Ref. [53] with

permission.

The mechanical properties of poly(α-hydroxyesters) could be

substantially improved by addition of calcium orthophosphates

[395, 396]. Shikinami and Okuno developed CDHA/PLLA composites

of very high mechanical properties [168]; mini-screws and mini-

plates made of these composites have been manufactured and

tested [388]. They have shown easy handling and shaping according

to the implant site geometry, total resorbability, good ability to

bond directly to the bone tissue without interposed fibrous tissue,

Search WWH ::

Custom Search