Biomedical Engineering Reference

In-Depth Information

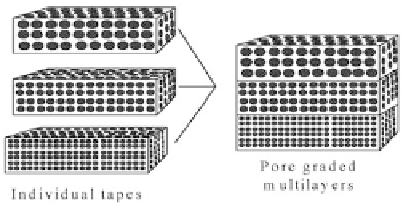

been fabricated [375, 411, 482, 484, 578-585, 588]. For example,

graded porous calcium orthophosphate bioceramics can be

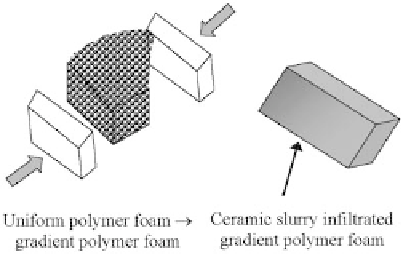

produced by means of tape casting and lamination (Fig. 4.12a). Other

manufacturing techniques, such as a compression molding process

(Fig. 4.12b) followed by impregnation and firing, are known as well

[375]. In the first method, a HA slurry was mixed with a pore former.

The mixed slurry was then cast into a tape. Using the same method,

different tapes with different pore former sizes were prepared

individually. The different tape layers were then laminated together.

Firing was then done to remove the pore formers and sinter the HA

particle compacts, resulting in graded porous bioceramics [582]. This

method was also used to prepare graded porous HA with a dense part

(core or layer) in order to improve the mechanical strength, as dense

ceramics are much stronger than porous ceramics. However, as in

the pressure infiltration of mixed particles, this multiple tape casting

also has the problem of poor connectivity of pores, although the pore

size and the porosity are relatively easy to control. Furthermore,

the lamination step also introduces additional discontinuity of the

porosity on the interfaces between the stacked layers.

Figure 4.12

Schematic illustrations of fabrication of pore-graded

bioceramics: (a) lamination of individual tapes, manufactured

by tape casting; (b) a compression molding process. Reprinted

from Ref. [375] with permission.

Search WWH ::

Custom Search