Biomedical Engineering Reference

In-Depth Information

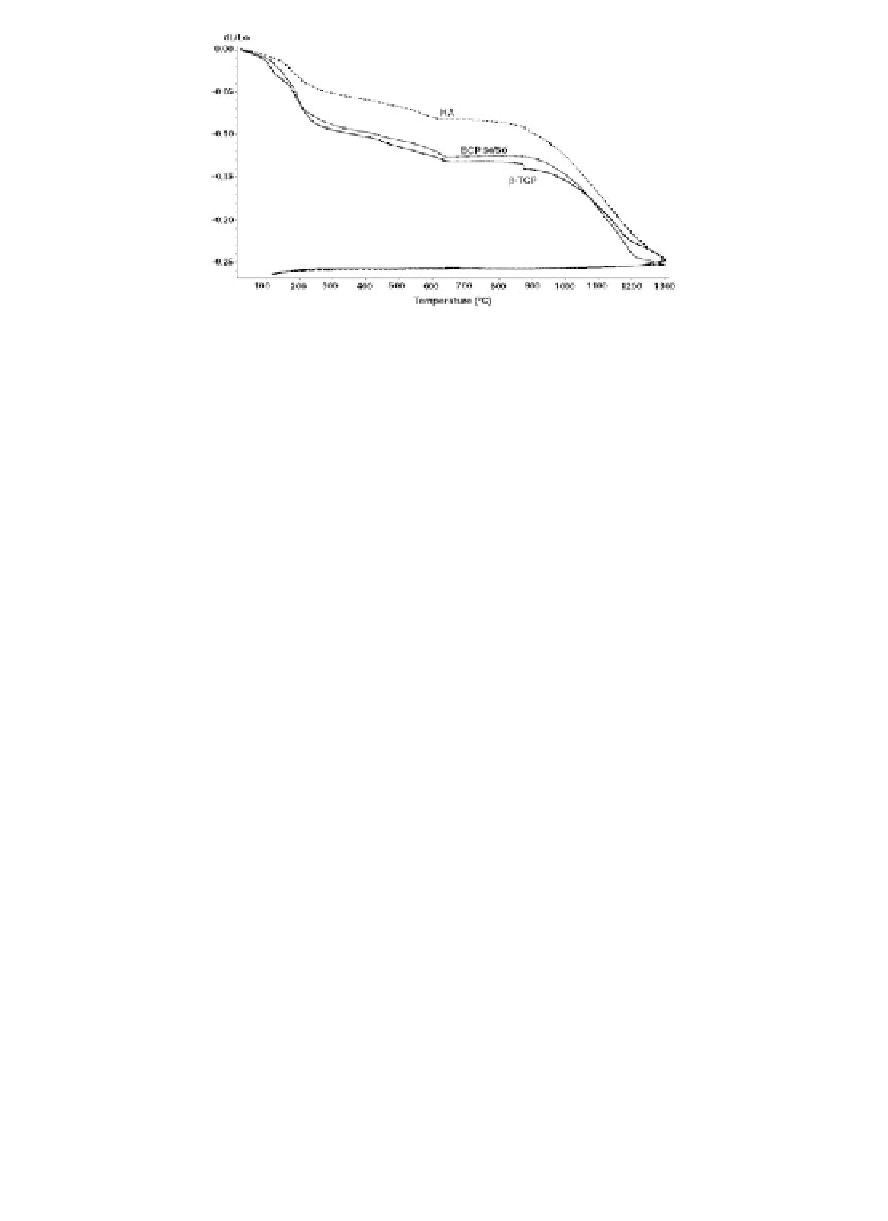

Figure 4.4

Linear shrinkage of the compacted ACP powders that were

converted into β-TCP, BCP (50% HA + 50% β-TCP) and HA upon

heating. According to the authors: “At 1300°C, the shrinkage

reached a maximum of approximately ~25, ~30 and ~35%

for the compacted ACP powders that converted into HA, BCP

50/50 and β-TCP, respectively” [243]. Reprinted from Ref.

[243] with permission.

An extensive study on the effects of sintering temperature and

time on the properties of HA bioceramics revealed a correlation

between these parameters and density, porosity, grain size, chemical

composition and strength of the scaffolds [256]. Namely, sintering

below ~1000°C was found to result in initial particle coalescence,

with little or no densification and a significant loss of the surface

area and porosity. The degree of densification appeared to depend on

the sintering temperature whereas the degree of ionic diffusion was

governed by the period of sintering [256]. To enhance sinterability

of calcium orthophosphates, a variety of sintering additives might be

added [257-260].

HA powders can be pressurelessly sintered up to the theoretical

density at 1000-1200°C. Processing at higher temperatures may

lead to exaggerated grain growth and decomposition because HA

becomes unstable at temperatures exceeding ~1300°C [64, 86,

145-151, 261]. The decomposition temperature of HA bioceramics

is a function of the partial pressure of water vapor. Moreover,

processing under vacuum leads to an earlier decomposition of HA,

while processing under high partial pressure of water prevents from

the decomposition. On the other hand, a presence of water in the

sintering atmosphere was reported to inhibit densification of HA and

accelerated grain growth [233, 262]. Unexpectedly, but application

Search WWH ::

Custom Search