Biomedical Engineering Reference

In-Depth Information

cases, the coatings are composed of uniform nanocrystalline

apatites (Fig. 3.7). They are capable in performing bone formation

and promoting direct osseointegration with juxtaposed bone

[566-569]. For example, an enhanced new bone formation can be

clearly seen on nanophase HA-coated tantalum compared to micro-

scale HA-coated tantalum and non-coated tantalum (see Fig. 2 in

Ref. [98]). Furthermore, nanostructured calcium orthophosphates

might be used as a coating material to impart surface bioactivity to

other materials, e.g

, glasses [570] and polymers [571, 572]. Finally

but yet importantly, such coatings might be patterned, e.g

.

, by laser

direct writing [491] or electrohydrodynamic atomization spraying

technique [573].

.

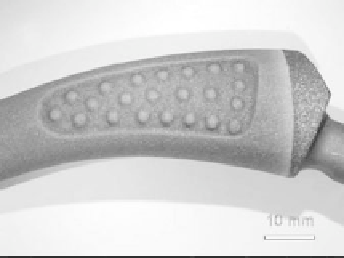

Figure 3.7

(a) A photo of a titanium implant coated with electrochemically

deposited HA at 37°C (Cenos

®

BoneMaster); (b) A micrograph

of a titanium implant surface coated with electrochemically

deposited HA at 37°C. Reprinted from Ref. [564] with

permission. Other micrographs of nano-CDHA coatings

biomimetically deposited on NaOH-treated Ti6Al4V surfaces

might be found in Ref. [565].

Search WWH ::

Custom Search