Biomedical Engineering Reference

In-Depth Information

technique of the nanodimensional and/or nanocrystalline

apatites. The term “hydrothermal” refers to a chemical reaction of

substances in a sealed heated solution above ambient temperature

and pressure [314] and this process allows synthesis of highly

pure fine-grained single crystals, with controlled morphology and

narrow size distribution [293]. Extraneous additives, such as EDTA

[311], surfactants [312], anionic starburst dendrimer [313], etc.,

might be utilized to modify the morphology of nanodimensional

and/or nanocrystalline apatites during the hydrothermal synthesis.

Most of these techniques produced rod-like crystals or whiskers,

while plate-like shapes were obtained in just a few studies [295,

305, 307].

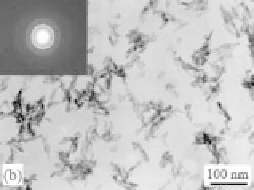

Figure 3.4

The influence of the reaction temperature on the crystal

dimensions of precipitated CDHA: (a) 25°C, (b) 37°C, (c) 55°C,

(d) 75°C.

Other preparation methods include sol-gel [30, 162, 199,

200, 237, 292, 315-326], co-precipitation [238, 293, 294, 327-

329], mechanochemical approach [54, 218, 303, 308, 330-335],

mechanical alloying [336, 337], ball milling [308, 332, 338, 339],

radio frequency induction plasma [340, 341], vibro-milling of bones

[342], flame spray pyrolysis [343], liquid-solid-solution synthesis

[344], electrocrystallization [133, 345, 346], microwave processing

Search WWH ::

Custom Search