Biomedical Engineering Reference

In-Depth Information

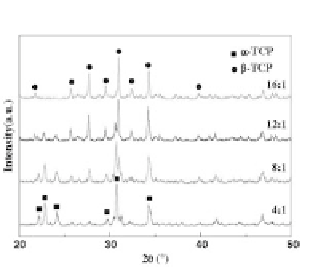

(a)

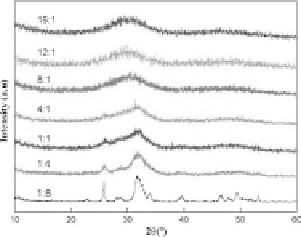

(b)

Figure 2.5

X-ray diffraction patterns of: (a) freeze-dried precipitates

prepared from aqueous solutions containing different amounts

of polyethylene glycol. Please, note a shift of the center of the

broadened peak from ~32° toward ~31° with increasing

polyethylene glycol/Ca molar ratio, which implies some

structural differences in the resulting ACPs; (b) heat-treated

(800°C) ACPs prepared from aqueous solutions containing

different amounts of polyethylene glycol. Reprinted from Ref.

[150] with permission.

2.3.2.3

Mechanical and pressure-induced techniques

In addition to the aforementioned solution-based methods, various

types of ACPs might be prepared by dry chemical techniques. For

example, an ACP was prepared using a mechano-chemical method

involving a dry mixture of DCPD and Ca(OH)

reactants with a Ca/P

ratio of 1.67 [155]. Other authors have shown that a prolonged high-

energy ball milling of either α-TCP, β-TCP powder in ethanol or a dry

mixture of ACP and DCPD powders lead to ACP formation after 24 h

[156-158]. Furthermore, prolonged high-energy ball milling of TTCP

was found to result in a mechanical activation with the formation of

undisclosed nanocrystalline and/or amorphous domains within the

compound [159]. However, there is a non-negligible risk of powder

contamination (ball wear) when using this processing route over

extended periods to obtain an ACP [31]. In addition, a crystalline

to amorphous transition has been detected for various calcium

orthophosphates at very high (up to 10 GPa) pressures (Fig. 2.6)

[160, 161].

2

Search WWH ::

Custom Search