Agriculture Reference

In-Depth Information

baked goods as an alternative to the addition of calcium propionate, which is

perceived as label unfriendly.

6.2.4 Natamycin

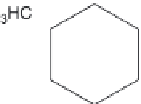

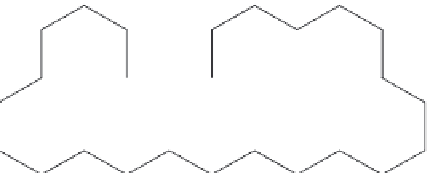

The polyene macrolide antifungal compound, natamycin (formerly pimaricin)

(Fig. 6.2) can also be considered natural because it is produced by fermentation of

the bacterium

Streptomyces natalensis

and closely related species. The name,

natamycin, is derived from the discovery of this strain in 1955 in a soil sample

from Natal Province in South Africa (Struyk

et al.

1958). Natamycin is now

produced as a commercial food preservative. Natamycin is used as an approved

food preservative worldwide, mainly for surface treatment of cheese and dried

sausages (the only authorisations in the EU) (Stark 1999; Thomas and Delves-

Broughton 2001; Delves-Broughton

et al.

2005). In the US, natamycin has GRAS

status and is allowed in cheese rather than on the surface. Its use in the US has

been extended to non-standard identity yogurt, cottage cheese, sour cream, cream

cheese, salad dressing and soft tortillas (FDA 2003a,b) and the surface of bread

(Delves-Broughton

et al.

2010). Use is much broader in South Africa where it was

fi rst discovered. In 2002, JECFA re-evaluated natamycin with a specifi c request to

assess the issue of antibiotic resistance (WHO 2002). This monograph reviewed

all aspects of the toxicity and safety of natamycin and its degradation products,

and reached very positive conclusions. Natamycin preparations are made by the

fermentation of sugar-based media.

Natamycin is active against nearly all yeasts and moulds but has no effect on

bacteria, protozoa or viruses. Its lack of activity against bacteria is of particular

benefi t in bacterial fermented or ripened food. The antifungal is active at very low

concentrations: most moulds are inhibited at 0.5-6.0 μg/ml, although some

Fig. 6.2

Structure of natamycin.

Search WWH ::

Custom Search