Environmental Engineering Reference

In-Depth Information

As Johnson [2] et al. mentioned, most conventional direct evaporative cooling methods

involve collection and recirculation of water to keep the wetting media or misting region

saturated. There exists an environment of almost stagnant water in direct contact with the

outside air, which aids, if not properly maintained at significant costs, the spread of many

liquid phase-born bacterial diseases, most notably Legionnaire's disease.

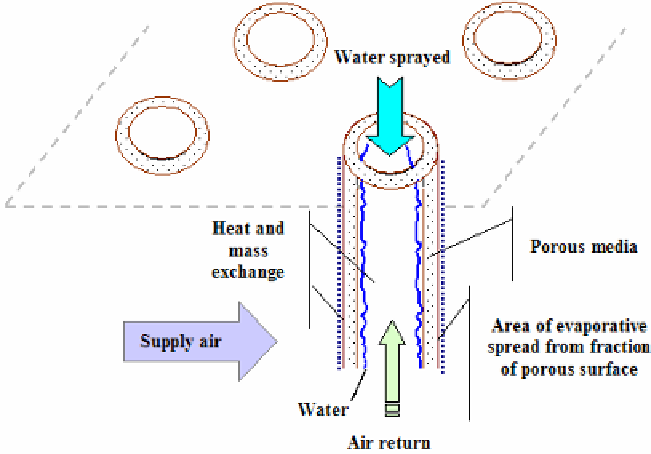

Due to this fact, indirect evaporative cooling application has been commonly used,

despite the fact that indirect systems have lower efficiency in comparison with direct systems

[3]. An evolution from indirect evaporative cooling systems is the semi-indirect evaporative

cooling system with porous media. The cooling effect of the impulsed air would thus be the

addition of two processes: the heat exchange between the two air flows (supply and return)

plus the heat exchange process, via evaporation, between the air supply and the external wall.

Depending on the permeability of the wall of the solid porous cooler which separates the two

air flows, there is greater or lesser liquid diffusion (water) with evaporation towards the air

flow supply from the external pores, in all cases. The absolute humidity of the air supply is

the controlling factor in this mass transport process, which is why it has been called semi-

indirect. The semi-indirect evaporative cooler works with the following mechanisms:

•

Heat and mass transfer in the return air flow.

•

Spread of mass due to porosity and heat transport through the solid wall.

•

Evaporation or condensation as well as heat and mass exchange in the air flow

supply.

Figure 3. Evaporative Cooler: heat and mass transfer mechanisms.

All of these features are presented together, thus combining heat and mass transfer,

increasing the cooling effect of the air to be conditioned and achieving optimisation of the

thermal process [4] (See Figure 3).