Environmental Engineering Reference

In-Depth Information

concentration produced a greater yield of HO but a reduced yield of WSO, while resulting in

negligible change in the formation of total oil products. The presence of 0.1M K

2

CO

3

dramatically enhanced organic conversion leading to a low yield of char, while the use of the

K

2

CO

3

suppressed the formation of both types of oils. The use of the two alkaline earth

metals catalysts, i.e., Ca(OH)

2

and Ba(OH)

2

, did not alter biomass conversion significantly,

but catalyzed the formation of WSO and produced much higher yields of total oil products.

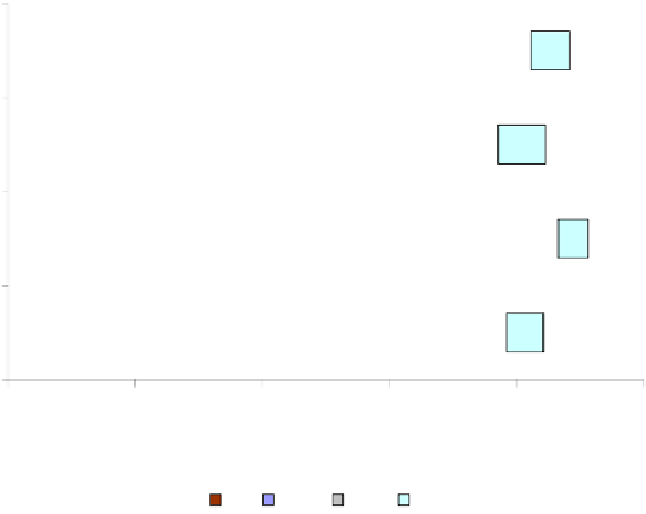

The liquefaction atmosphere (inert or reducing) was found to be another important factor

influencing the liquefaction process. As shown in Figure 7, it was demonstrated that the

reducing atmosphere (i.e., H

2

) in the liquefaction process promoted the HO formation while

suppressing the WSO formation. With the presence of 0.1M Ca(OH)

2

and 2MPa H

2

,

liquefaction of the sludge powder in water at 280

o

C for 60 min produced a high yield of HO

(26 wt%), almost two times as high as that in N

2

(13.6 wt%), and it produced total oily

products (HO+WSO) at a yield as high as 60 wt%.

Ca(OH)2

26.0

34.2

22.0

6.2

Liquefaction in H

2

None

21.0

35.6

20.6

7.3

Ca(OH)2

13.6

51.4

21.5

4.8

Liquefaction in N

2

None

5.7

20.3

36.9

21.3

0

20

40

60

80

100

280

o

C, 60 min

9.1 wt% biomass

Initial gas pressure: 2 MPa

Yield (wt%, daf)

HO

WSO

Char

Gas

Figure 7. Variation in the product yields with different liquefaction atmospheres (N

2

and H

2

) (adapted

from Xu and Lancaster, 2008).

In Xu and Lancaster's (2008) work, the energy output/input ratios, calculated based on

Eq. (1), were all <1.0, suggesting that the liquefaction operation tested, in a batch reactor, was

energy inefficient. However, the energy efficiency can be improved by employing a flow-type

reactor and installing a heat exchanger to pre-heat the reactor feed stream using the hot

product stream as well as by combusting the resulting chars/gases to provide a portion of the

heat for the process. Liquefaction of sludge in H

2

, irrespective as to whether a catalyst was

present or not, resulted in significantly improved net energy efficiencies. However, the

operation in H

2

with the presence of Ca(OH)

2

catalyst dramatically enhanced the efficiency to

as high as 0.76.