Environmental Engineering Reference

In-Depth Information

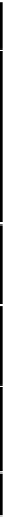

Table 2. Typical properties of pyrolysis bio-oil and of a petroleum-based

heavy fuel oil (Czernik and Bridgewater, 2004).

Physical property

Bio-oil

Heavy fuel oil

Moisture content (wt %)

15-30

0.1

pH

2.5

-

Specific gravity

1.2

0.94

Elemental composition (wt %)

C

54-58

85

H

5.5-7.0

11

O

35-40

1.0

N

0-0.2

0.3

ash

0-0.2

0.1

HHV (MJ/kg)

16-19

40

Viscosity (at 50

o

C, cP)

40-100

180

Low temperature pyrolysis with reactor temperature <500

o

C has also been widely

adopted for the treatment of sewage sludge in order to promote the oil yields and to minimize

heavy metal evaporation. For a pyrolysis temperature maintained between 500 and 600°C,

heavy metals in the sludge (except mercury and cadmium) could be safely retained within the

solid chars (Kistler and Widmedz, 1987; Karayildirim et al., 2006). Cadmium has a lower

evaporation temperature than most other metals and is dispersed into the gas phase at about

60°C, but can be condensed in gas-cleaning and scrubbing equipment with relative ease,

while mercury can be completely evaporated at temperatures above 350°C and is difficult to

eliminate from the gas stream (Furness et al., 2000). As an extension of standard pyrolysis, an

oil-from-sludge (OFS) process has been developed with the system arranged to maximise the

production of high quality oil, which can be used as a fuel (Bridle and Hertle, 1998). In the

OFS process, pre-dried sludge (25% DS) is heated to 450°C for a heating period of about 30

minutes under anoxic conditions and at a pressure just above atmospheric, until about 50% of

the sludge is evaporated. The vapours are then contacted with residual tar to catalyze the

formation of high caloric value hydrocarbons. The process can produce 200-300 litres of oil

per tonne of dried sludge. In comparison with incineration and anaerobic digestion, 95-98%

of the energy in the dried sludge is recovered in the various products, and the net energy

efficiency could be greater. However, the energy input for pyrolysis, including energy

consumption for thickening, drying, and heating of the sludge feedstock to necessitate the

pyrolysis process, is still fairly high. While the data of energy consumption for thickening of

the sludge is unavailable, the energy consumption required to dry thickened waste activated

sludge (TWAS) containing about 10% TS to a dry sludge at 105°C is about 2220 kJ/kg-ws,

according to Kim and Parker (2008). This is a significant portion of the energy consumption

for pyrolysis. Kim and Parker (2008) also found the energy consumption for increase of