Environmental Engineering Reference

In-Depth Information

∑

(HHV

of

the

product)

×

(mass

of

the

product)

Energy Output/Input Ratio =

(1)

(Energy

Input)

The approximate energy efficiency of each process can be estimated by the equation

above, while depending on different requirements and characteristics of each process, the

energy input calculation may differ method to method and may be difficult to determine due

to shortage of experimental data reported.

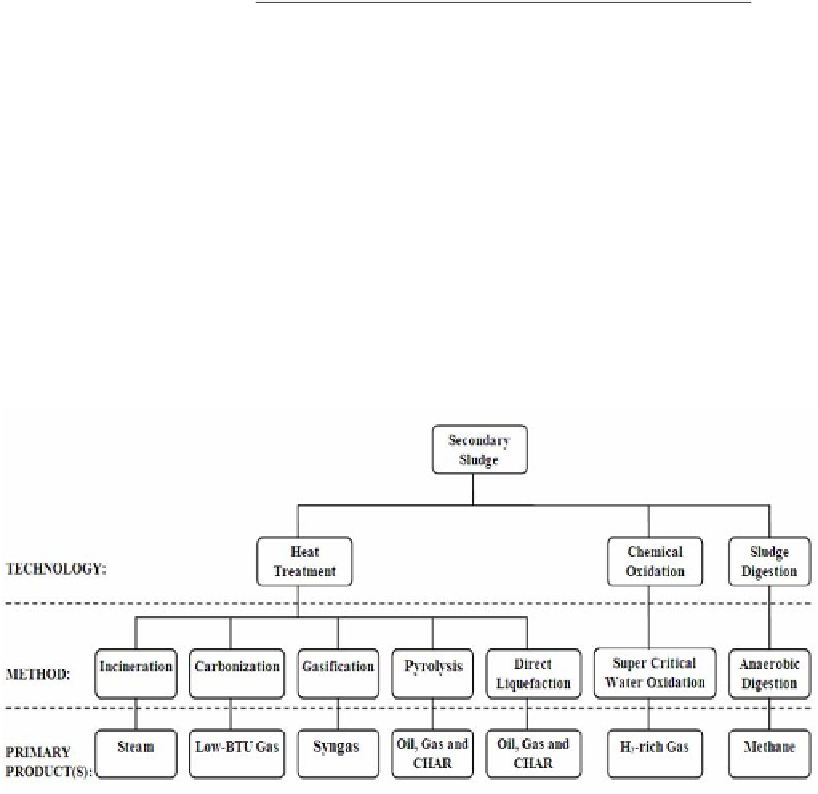

The objective of this chapter is to provide an overview of different types of post-

treatment methods of secondary sludge, i.e., waste activated sludge (WAS), for energy

recovery. Emphasis is put on the discussion on the energy efficiency for each process, while

advantages and disadvantages of each process are also highlighted. An outline of the many

post-treatment options and their primary energy products can be summarized in Figure 2. A

description of each treatment method including incineration, gasification, pyrolysis, direct

liquefaction, super critical water oxidation and anaerobic digestion follows.

Figure 2. Outline of treatment options of secondary sludge for energy production

2.

S

ECONDARY

S

LUDGE

T

REATMENT

M

ETHODS

Secondary sludge can be treated by employing a variety of post-treatment technologies

such as heat treatment, chemical oxidation and sludge digestion whose processes have been

overviewed recently by Mahmood & Elliot (2006).

2.1. Incineration

Incineration technology is the controlled combustion of waste with the recovery of heat

to produce steam that in turn produces power through steam turbines (Kumar, 2000). A

general flow diagram of the incineration process is depicted in Figure 3. It shows that the

sludge is fed into the boiler, which could be rotary kiln, fixed bed furnace or, common in the