Environmental Engineering Reference

In-Depth Information

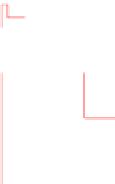

TPA

Ker o

LDO

160.5 C

185.1 C

241. 2 C

I PA- a

253. 9 C

84.5 C

90.8 C

127 C

138.8 C

137.1 C

37.45 C

E-1

E-2

E- 3

E- 4

75 C

75 C

103.3C

105 C

134. 2 C

60 C

Desal t er

61C

40 C

Flash Vap

I PA- b

253.9C

193. 8 C

E-5

BPA

199.4 C

327.5 C

141.2 C

HDO

137.1 C

318.2 C

378 C

145 C

80 C

276. 6 C

Fl ash Drum

200 C

E- 8

183. 9 C

E-6

E- 7

193. 7 C

RCO

275.8 C

346. 4 C

225. 7 C

186.3 C

60 C

Furnace

E-9

275. 4 C

220 C

RCO

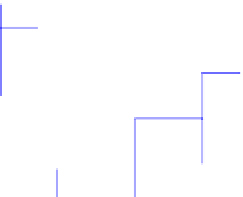

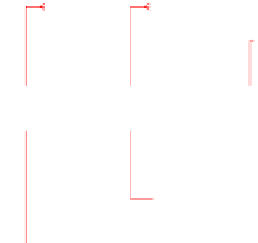

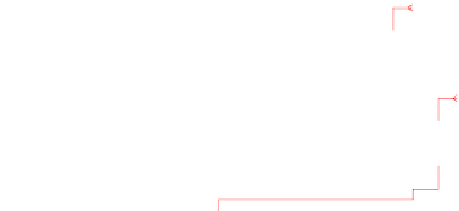

Figure 13. Crude Atmospheric Distillation Unit HEN (III)

The third network shown in figure 13 set the right compromise to some facilities. It is

designed differently than the first network since it does not use the pinch design method.

However, some sense of systematic technique has been also used here. This network design

evolves from the simplest design desired by most of the process owners and plant operators. It

has less number of units, no splits, less possibility of fouling and frequent cleaning needs,

easy to operate and more importantly less area and capital cost.

The pre-heat train in Figure 13 kept the simple design before the desalter almost as it is

and focused only on the heating utility minimization. It tried to push the temperature before

the crude heater from 265 ºC in the simple design to about 276 ºC in the new design via better

heat recovery in the area after the pre-flash drum only. A systematic technique can be used

for that purpose via enumerating all matches possibilities between the crude stream, after the

pre-flash drum, and all hot streams available at temperatures higher than its supply

temperature. Simulating these possibilities only and then ranking them based upon the impact

on the heating utilities requirement but with only one split in the crude stream after the pre-

flash drum to avoid increasing fouling, will conclude this step and move the approach to the

second step. The second step is to reconcile the selection of the new matches after the pre-

flash drum with that before it. The possibilities that can arise can also be ranked based upon

the level of simplicity in it.

The point that we are trying to make here in this crude unit pre-heat train design approach

is that instead of designing the heat exchanger network using pinch design method to get the

best possible waste heat recovery scheme and try an ad hoc approach to simplify the network,