Environmental Engineering Reference

In-Depth Information

utilities. However, in some situation we can have a trade off between heating utilities cost and

benefits obtained from reducing power import or exporting power to the grid.

With the aid of GCC we might find situations in which it is better from work generation

point of view to use cold water above the pinch to produce steam and generate electricity,

then using steam turbines exhaust for process heating than literally doing process to process

integration using minimum approach temperature

∆

T among hot and cold process streams

much higher than the originally selected minimum approach temperature

∆

T_min.

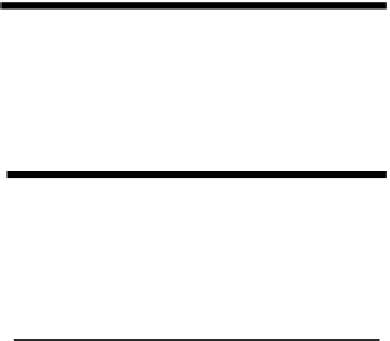

HP Boiler

HP

Proc. #1

HP Process

Condensate

Proc. #2

MP Boiler

chemicals

MP

Vent

MP Process

Condensate

Proc. #4

Proc. #1

Vent

Deaerator

LP

BFW

Raw water

Make-up

Effluent

LP Process

Condensate

Proc. #1

Treatment Plant

Proc. #3

Process Condensate

Figure 19. Combined Heat and Power System Example

In summary, the Grand Composite Curve can be utilized to help optimize combined heat and

power systems (CHP) shown in figure 19, select the load and return temperature of hot oil

circuits, best integration between process and furnaces exhaust and process refrigeration

levels as well as the synthesis of the multiple-cycle refrigeration systems [1,3].

H

EAT

E

XCHANGERS

N

ETWORK

(HEN)

S

YNTHESIS

Upon deciding on process reaction-separation system design, the optimization of major

design variables such as reactor conversion, selectivity, recycle inert concentration, etc.,

minimization of process waste, minimization of utility waste via heat integration, process

modifications for the sake of more heat integration has been explored and the plant utility

system is configured, the material and energy balance can now be more or less fixed and

hence the hot and cold streams which contribute to the heat exchanger network can be