Environmental Engineering Reference

In-Depth Information

Biomethane

combustion

0.5%

Other

0.5%

Biofuel combustion

in ca rs

10%

Manufacture of

auxiliary materials

20%

Feedstock

provision

55%

Residue

combustion

14%

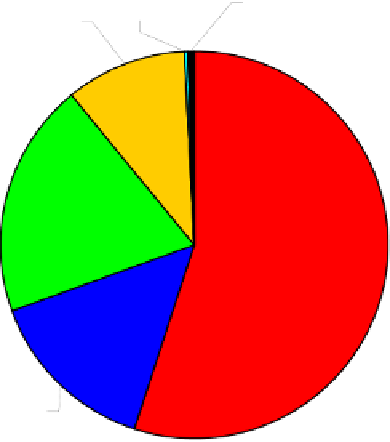

Figure 18. Contributions to the total GHG emissions of the biorefinery system. “Other” includes

wastewater treatment, waste disposal (mainly ashes) and uncontrolled CH

4

emissions from anaerobic

digestion.

Contributions from all the stages to the total GHG emissions of the biorefinery system are

illustrated in Figure 18. More than half of the GHG emissions are due to feedstock provision,

i.e. collection, processing and delivery of wood residue pellets.

Concerning the fossil reference system, the total GHG emissions are mainly due to

gasoline (68%), followed by electricity (12%) and then other products. Detailed information

concerning the contributors to the total GHG emissions of the fossil reference system are

reported in Table 7. The primary energy demand of biorefinery system and fossil reference

system has similar contributions than those of GHG emissions.

Results highlight both the importance of generating high quantities of electricity and the

benefits deriving from an utilization of the process heat produced for achieving high GHG

emission and fossil energy savings. Concerning electricity, the lower the share of electricity

sent to alkaline water electrolysis, the higher the savings. In the determination of the

magnitude of these savings, a fundamental role is played by the fossil reference system

considered. It is assumed that the fossil reference system produces electricity from natural gas

but the savings would be larger if, for instance, electricity from coal or oil is displaced.

Regarding the heat, fundamental is the possibility to use it in an application located in the

surrounded of the biorefinery, maximizing the environmental benefits which can be gained. In

the fossil reference system, heat is assumed to be produced from oil and even in this case,

environmental savings would be larger if coal-derived heat is replaced. The differences

between biorefinery systems with and without process heat utilization are reported in the